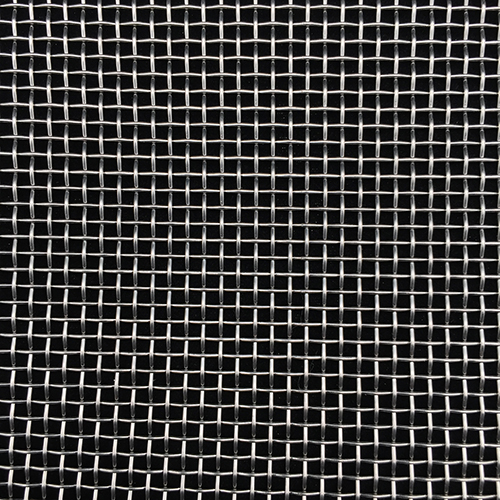

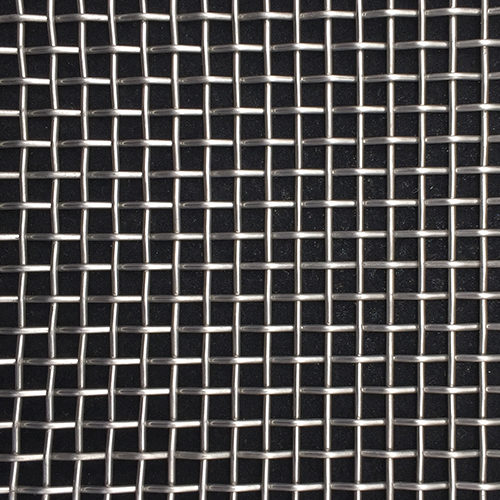

Dutch Weave Wire Mesh Application: Speaking of Stainless Steel Wire Mesh, we all know that it is used for filtration. The coarse filter is thick with mesh, and the fine filter is dense with mesh. Today looper will introduce you. Dutch Weave Wire Mesh is mainly used for sieving and filtering under acid and alkali environment conditions, the oil industry as a mud net, the chemical chemical fiber industry as a sieve screen, the electroplating industry as a pickling net, gas, liquid filtration and other medium separation. Generally, stainless steel wire, nickel wire and brass wire are used as materials. The wire weaving dense mesh is arranged in a dense arrangement of weft and silk, and there are five methods of plain weave, twill weave, plain dutch weave, twill dutch weave, and reverse Dutch weave. The size of the stainless steel wire mesh is 5 mesh – 630 mesh, 1 meter – 8 meters wide.

Dutch Weave Wire Mesh is an industrial fabric which is woven with raw materials such as silk, metal wire or synthetic fiber, has uniform and stable vent holes on the surface, and has screening and filtering effects. The mesh of the screen is customarily called. The size of the screen is often expressed in terms of the number of holes per unit length (mesh) and also the width of each hole. China’s national standards are expressed in terms of the number of holes per centimeter, such as 20 holes/cm. Dutch Weave Wire Mesh is a wire mesh group of different meshes supported by the sieve plate before the material of the extruder, and its function is to filter the melt flow and increase the flow resistance, thereby filtering out mechanical impurities and improving the effect of mixing or plasticizing. . If the filter is filtered into large pieces of debris (such as paper), it will suddenly fail completely, which will quickly bring the pressure of the extruder filter to a peak. Therefore, in order to prevent this from happening, there must be a safety system such as a safety diaphragm, a safety pin or an alarm connected to the pressure gauge.

Dutch Weave Wire Mesh is generally not corroded, but nothing is absolute. The corrugated fracture of Dutch Weave Wire Mesh is a corrosive fracture that occurs under the action of stress and corrosive environment. Generally speaking, in the corrosive environment, Dutch Weave Wire Mesh will accelerate the rate of corrosion damage after being subjected to external stress. The simple case is the result of the superposition of these two factors. In a specific corrosive environment, when the metal material is not stressed, the corrosion damage is minimal, and when subjected to a certain stress, although the stress is sometimes much lower than that of stainless steel. The strength limit of the net itself, after a period of time, even the ductile stainless steel mesh will also break. This kind of destruction is often without any omen, and the damage caused is very serious and often catastrophic. There are roughly three prerequisites for stress corrosion cracking:

1, a special environment,

2, must be subjected to tensile force;

3, stainless steel mesh itself is of poor quality.