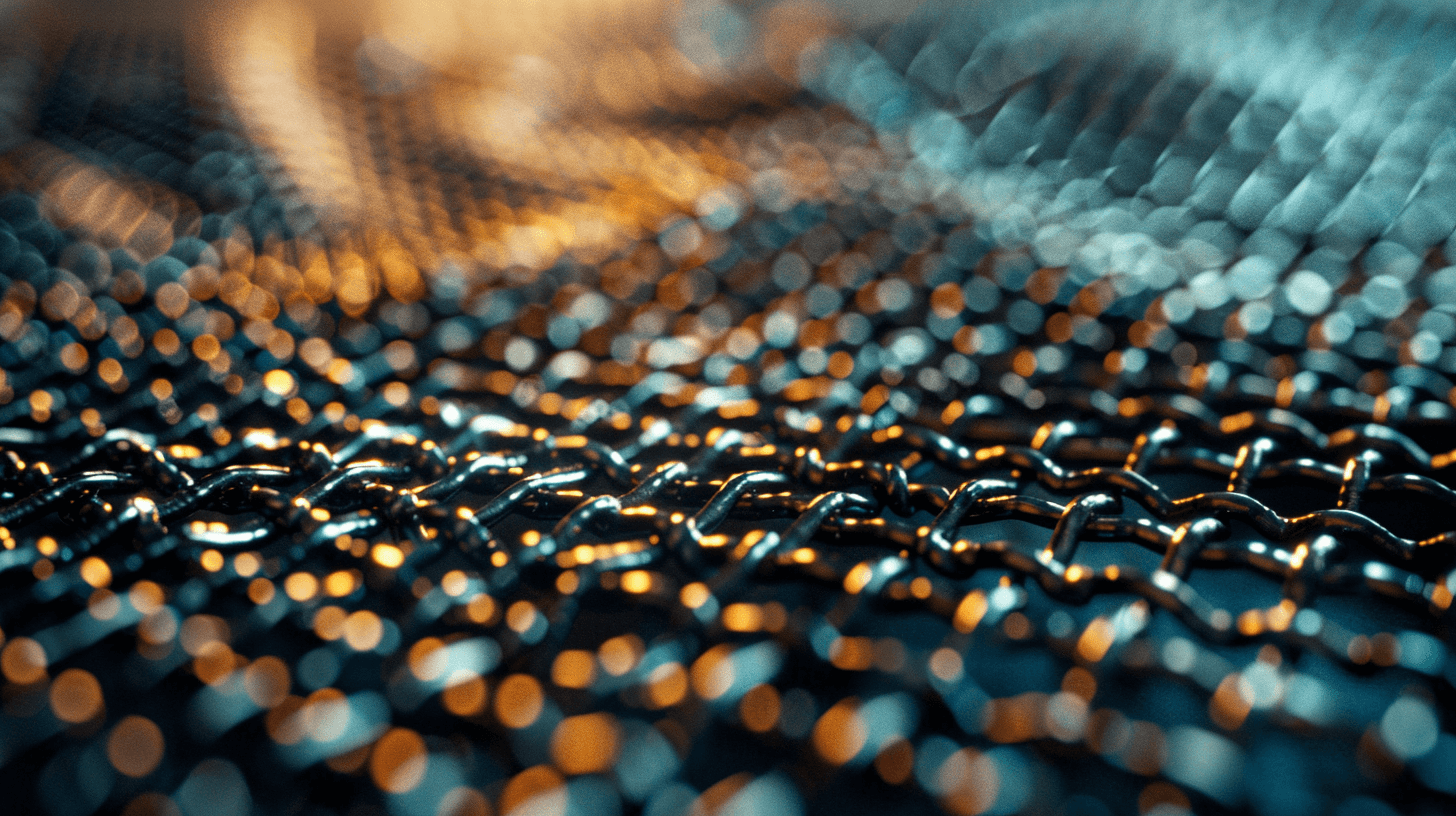

The stainless steel wire mesh production line consists of seven processes, a brief introduction here. If you are interested in the seven processes of the stainless steel wire mesh production line, you can leave a message. I will introduce it in future news.

First, Stretch the wire diameter to the specified size.

Second, Organizing warp wire

Third, Pass the wire through the heald and the steel shovel.

Fourth, Tied to the machine.

Fifth, The machine starts to automatically weave.

Sixth, Move the woven finished stainless steel wire mesh to the inspection station.

Seventh, Inspection

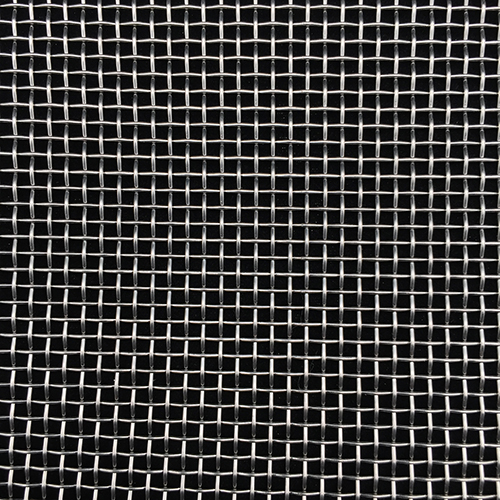

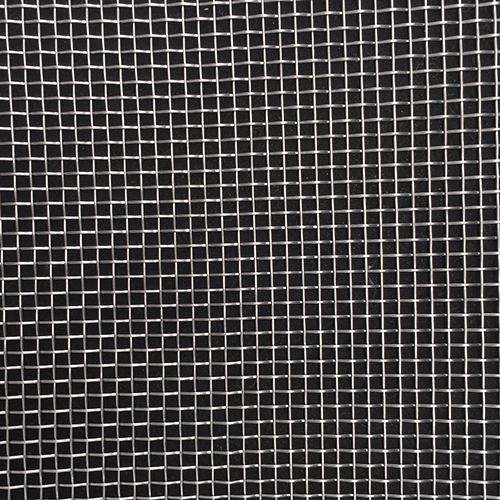

1.Stainless steel wire mesh inspection

(1) Inspection of weaving accuracy

(2) Inspection of weaving quality

(3) Inspection of wire diameter

(4) Inspection of stainless steel wire mesh width and stainless steel wire mesh length

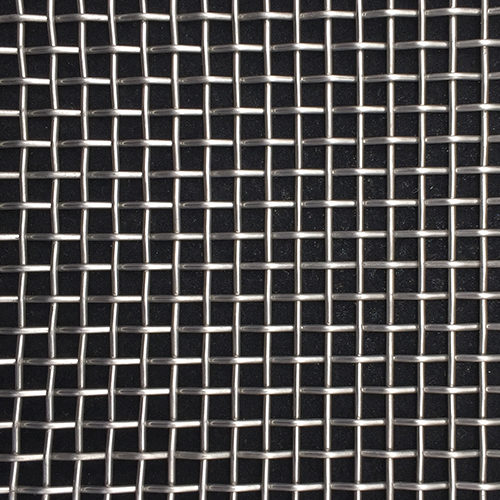

2. Dutch weave wire mesh inspection

(1) Warp and weft density test

(2) Weaving quality inspection

(3) Inspection of dutch weave wire mesh width and dutch weave wire mesh length

(4) Inspection of wire diameter