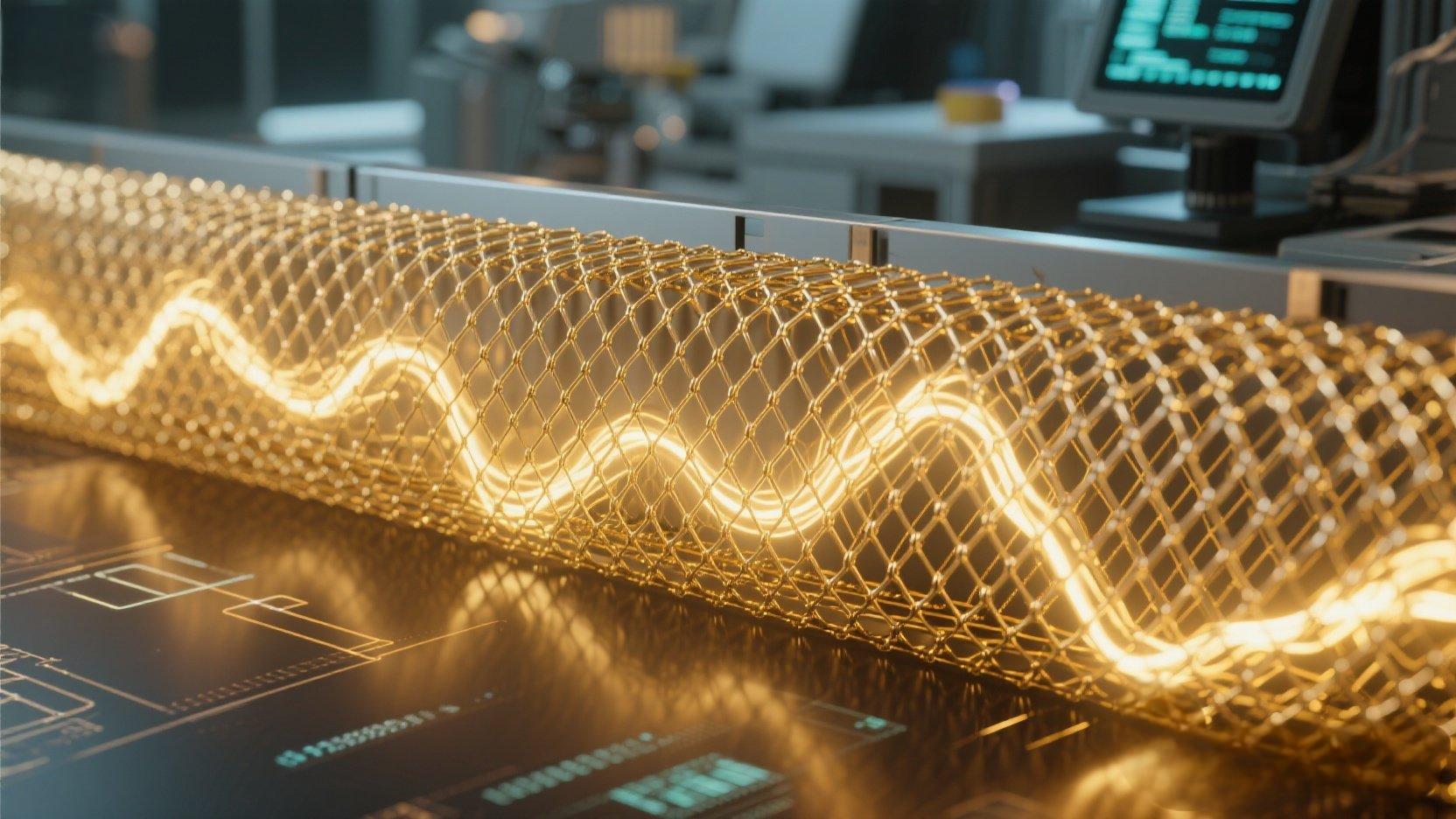

As industries become increasingly dependent on electronics, protecting sensitive equipment from electromagnetic interference (EMI) is more crucial than ever. Brass wire mesh has emerged as an effective and reliable material for EMI shielding. In this blog, we explore the properties of brass wire mesh, its shielding capabilities, and where it’s used in high-EMI environments.

H2: What is Electromagnetic Shielding?

H3: Sources of Electromagnetic Interference (EMI)

EMI can come from various sources—radio signals, wireless networks, electrical equipment—and can disrupt the function of sensitive devices. In industrial settings, this interference can result in equipment malfunctions or data corruption.

H3: How Shielding Materials Work

Shielding materials, like brass wire mesh, work by reflecting or absorbing electromagnetic waves, preventing them from penetrating protected spaces or devices.

H2: Why Choose Brass Wire Mesh for EMI Protection?

H3: Conductivity and Effectiveness

Brass is a copper-zinc alloy with excellent electrical conductivity, making it highly effective at blocking and redirecting EMI. Its fine wire mesh structure creates a barrier while maintaining airflow.

H3: Corrosion Resistance and Lifespan

Compared to pure copper, brass offers better resistance to corrosion, especially in environments with moisture or chemicals, ensuring long-term performance.

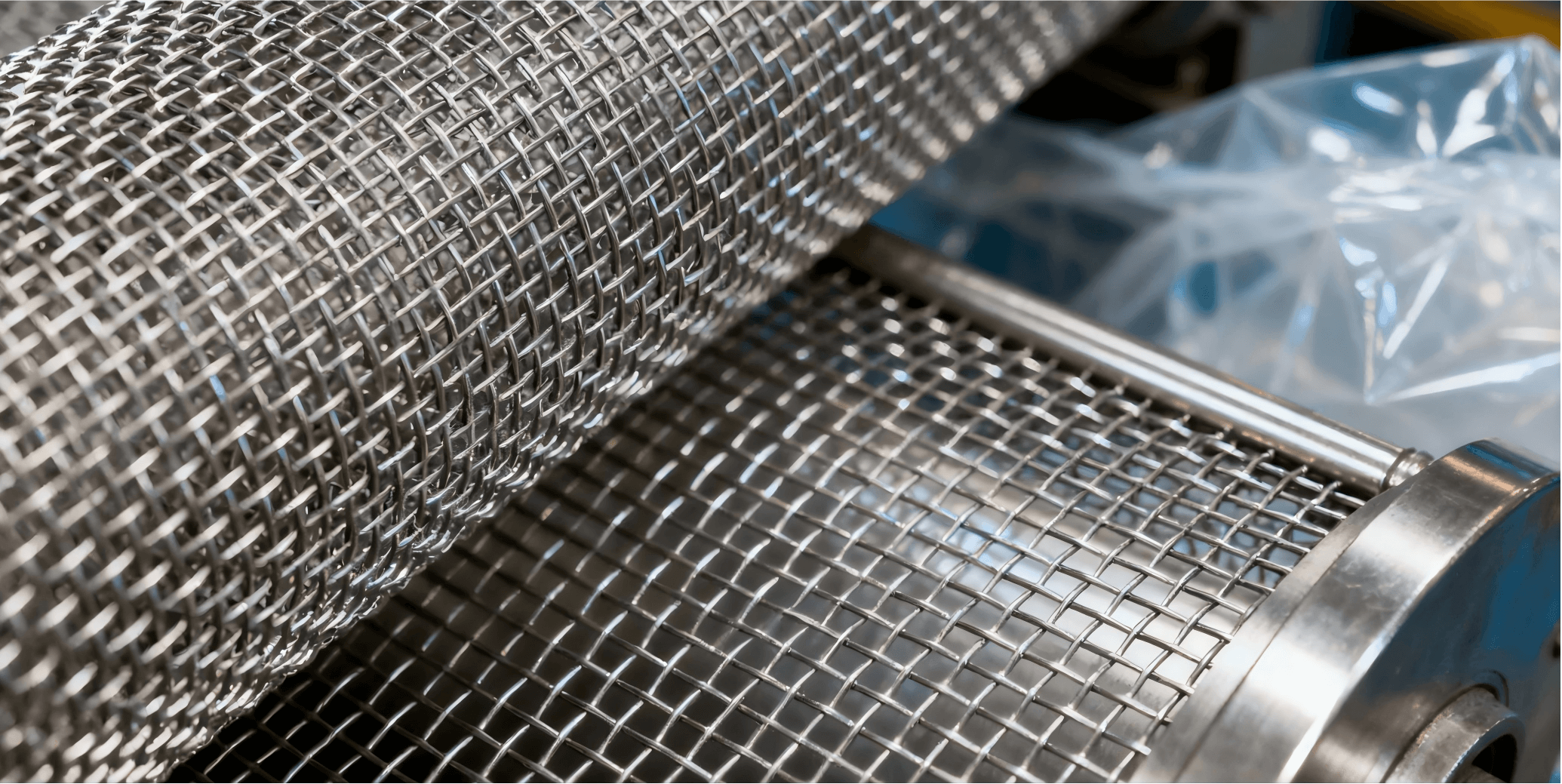

H3: Flexibility and Fabrication Benefits

Brass mesh is easy to cut, shape, and form, making it suitable for custom shielding enclosures, wraps, or filters in complex assemblies.

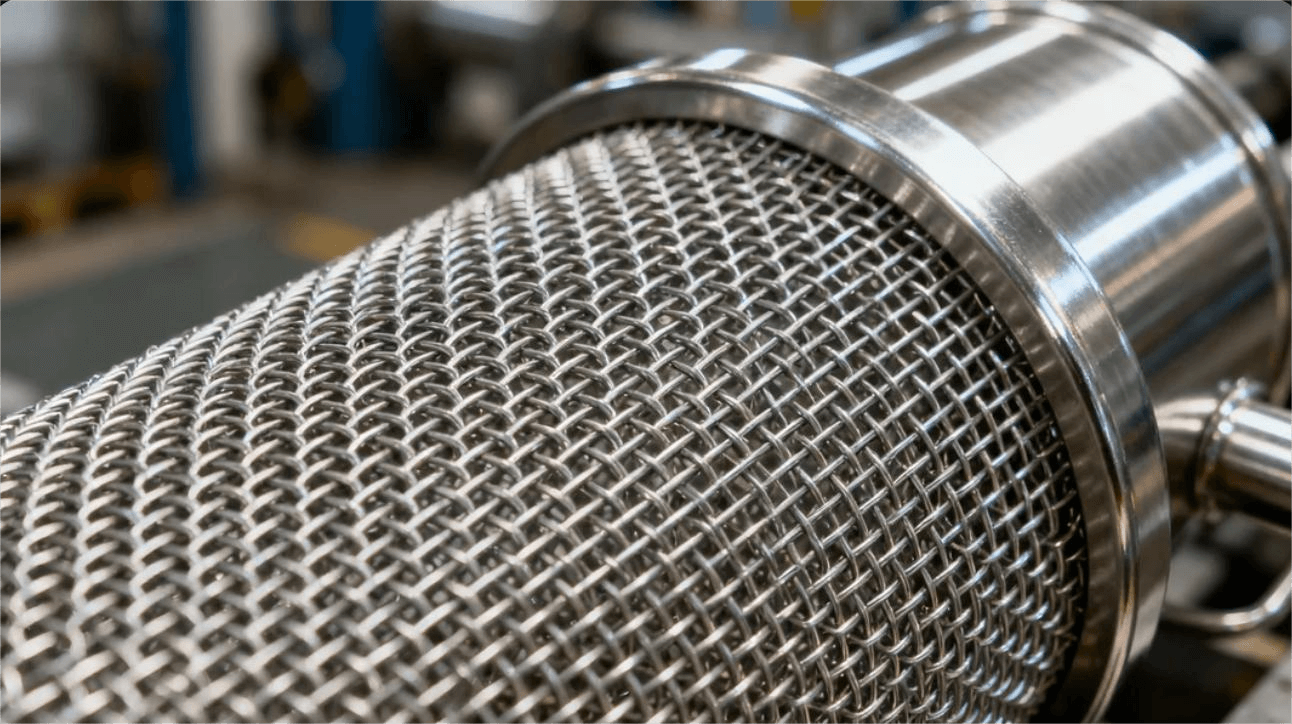

H2: Industrial Applications of Brass Mesh in EMI Shielding

H3: Shielded Enclosures and Cabinets

Brass wire mesh is used to line or wrap around metal enclosures to protect internal components from external EMI sources.

H3: Medical and Laboratory Equipment

In medical imaging or diagnostic labs, where precision and low-noise environments are critical, brass mesh ensures equipment reliability.

H3: Telecommunications and Data Centers

Brass mesh helps isolate sensitive networking equipment and prevents signal leakage or cross-interference between servers and transmitters.

H2: How to Select the Right Brass Wire Mesh for Shielding

H3: Mesh Count and Aperture Size

Choosing the right mesh size is crucial—higher mesh counts offer better shielding for high-frequency interference.

H3: Brass vs. Other Metals (Copper, Stainless Steel)

While copper offers higher conductivity, brass provides better cost-efficiency and corrosion resistance. Stainless steel is more durable but less conductive.

H3: Customization Options for Specific EMI Requirements

Work with a manufacturer that offers custom mesh panel sizes, wire diameters, and frame integration for complete EMI shielding solutions.

📞 Conclusion

Brass wire mesh is a powerful solution for electromagnetic shielding across a wide range of industrial sectors. Its blend of conductivity, durability, and ease of fabrication makes it an ideal material to protect sensitive electronics. To find the best brass wire mesh for your shielding needs, contact our technical team today.