Micro Wire Mesh for Filtration Systems: Precision and Efficiency in Every Strand

Filtration systems across industries—from chemical processing to aerospace—depend on precision, durability, and reliability. Micro wire mesh for filtration systems offers a highly efficient and customizable solution, capable of capturing even the finest particles without compromising flow rates or structural integrity. In this post, we’ll explore its advantages, applications, and how to choose the right configuration for your needs.

What Is Micro Wire Mesh?

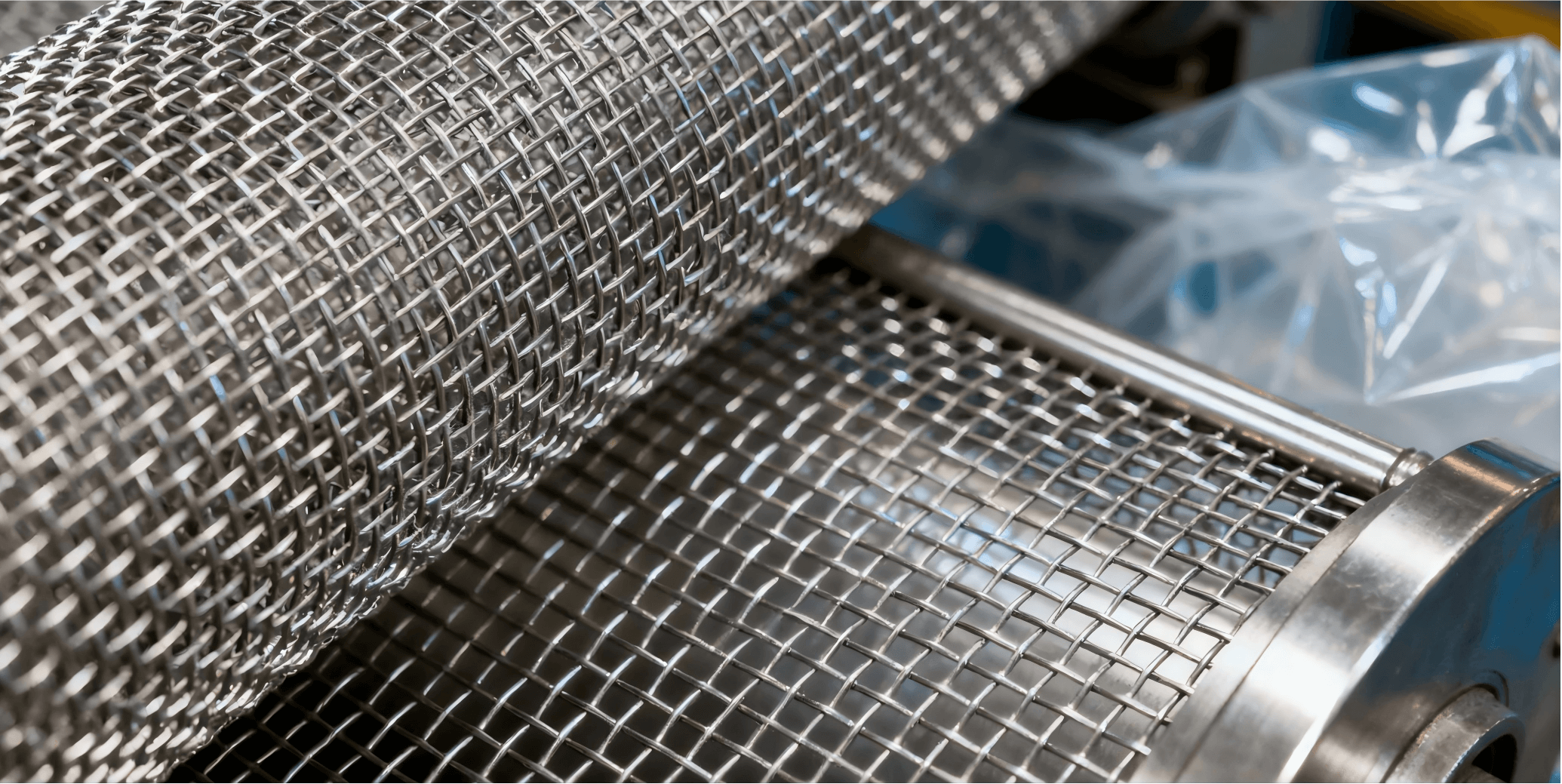

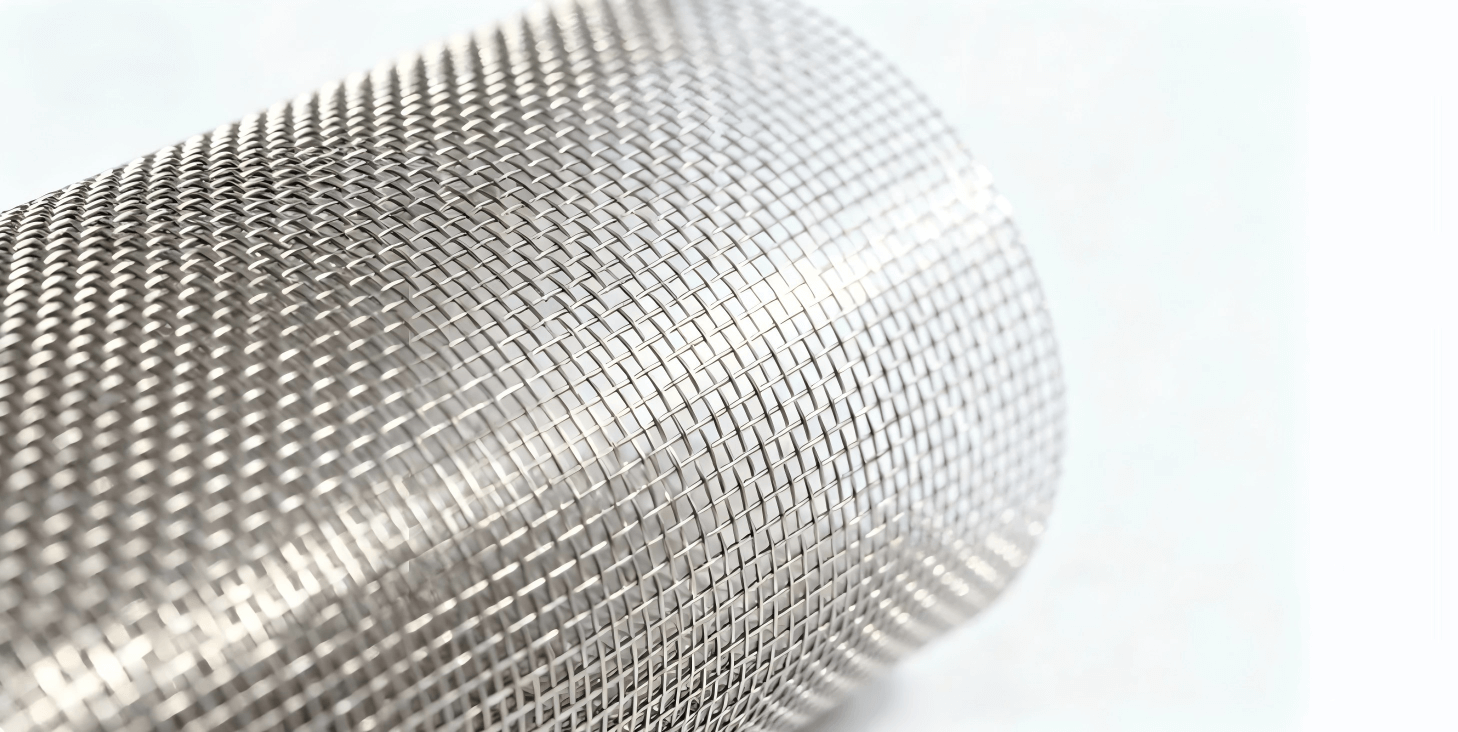

Defining Mesh Count and Wire Diameter

Micro wire mesh typically features very high mesh counts (ranging from 80 to over 400) with ultra-fine wire diameters. This results in extremely small openings ideal for fine filtration.

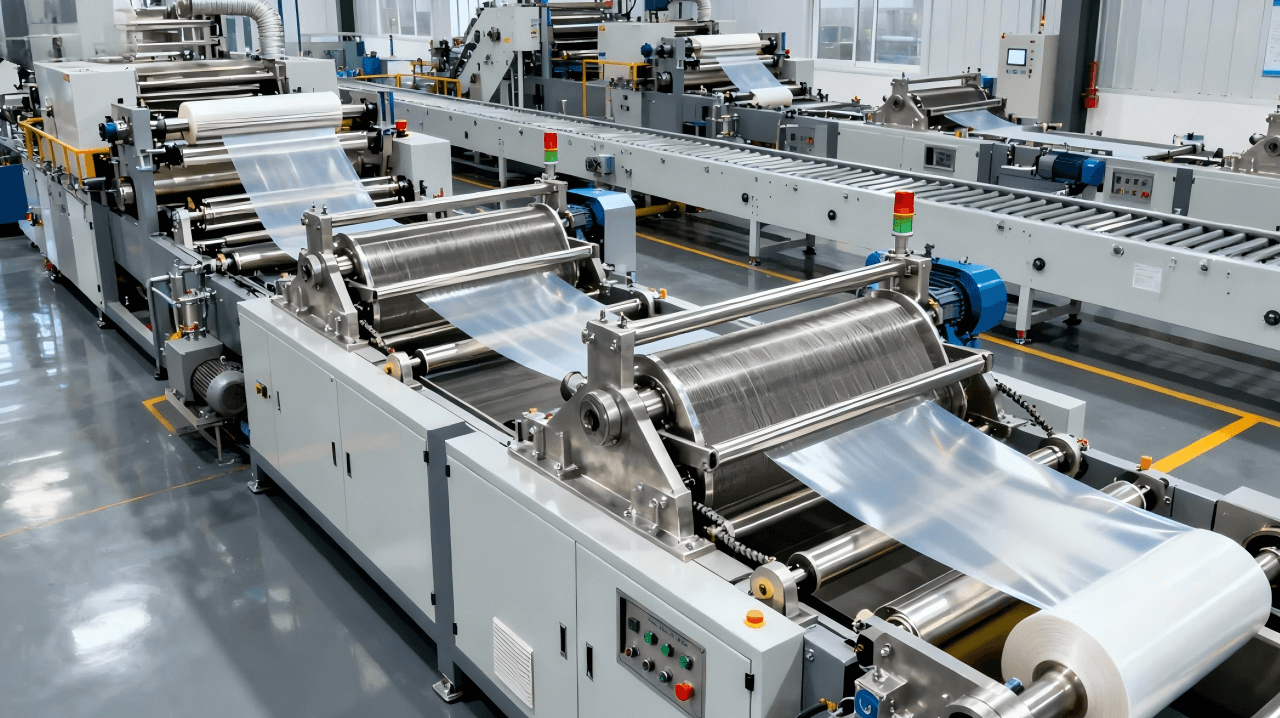

Manufacturing Methods and Materials

Manufactured via precision weaving techniques, micro mesh can be made from stainless steel, nickel alloys, Monel, or even phosphor bronze—each selected based on chemical resistance and application.

Why Micro Wire Mesh Is Ideal for Filtration Systems

High Precision Particle Retention

Micro mesh traps particles down to microns or sub-microns in size, making it ideal for sterile filtration, chemical processing, and microfluidic systems.

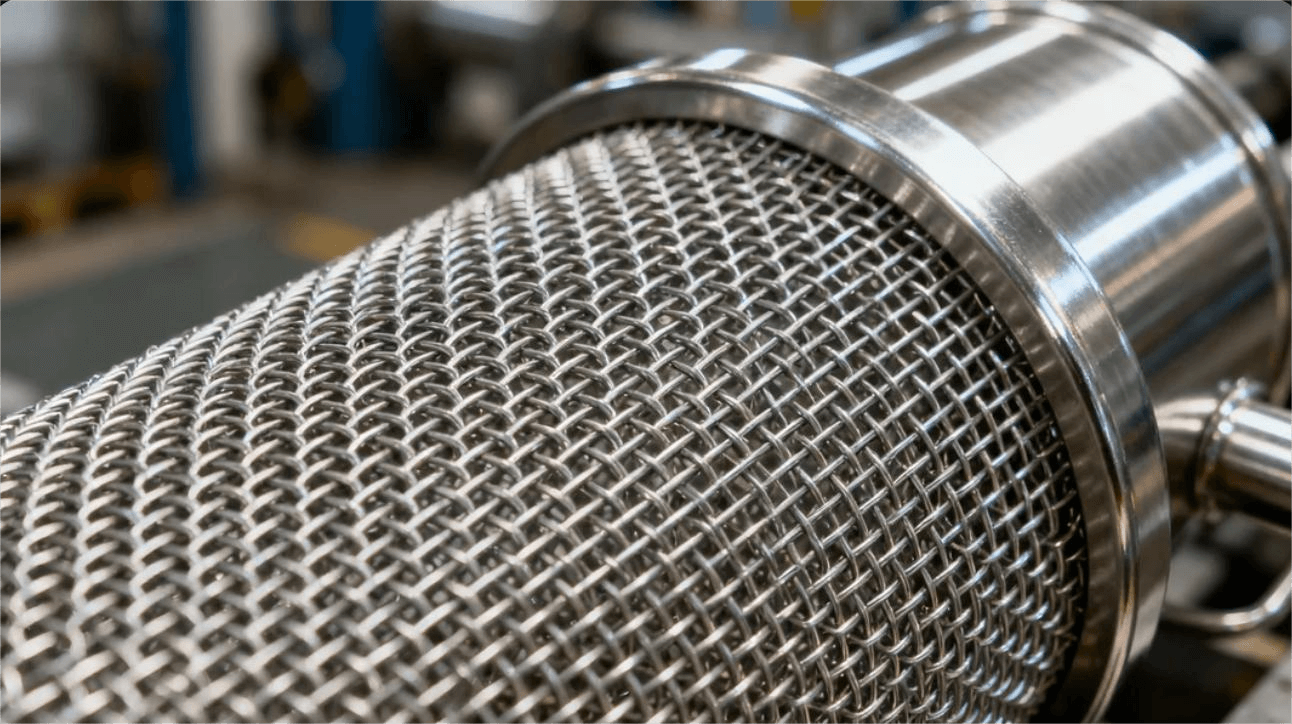

Corrosion and Heat Resistance

When constructed from stainless steel or Monel, micro wire mesh withstands harsh chemicals, pressure, and temperature—ideal for demanding industrial environments.

Cleanability and Reusability

Unlike disposable filters, micro mesh filters can be backflushed, ultrasonically cleaned, or steamed—ensuring long-term cost efficiency.

Applications Across Industrial Filtration Fields

Liquid Filtration in Chemical Plants

Used to separate solids from aggressive liquids, micro mesh provides exact particle separation, ensuring purity and process integrity.

Air Filtration in HVAC and Cleanrooms

Micro mesh improves indoor air quality by blocking fine airborne contaminants, especially in cleanroom environments or high-efficiency HVAC systems.

Oil and Fuel Filtration in Automotive and Aerospace

Used in hydraulic systems, engines, and fuel lines, micro mesh filters remove micro-debris to protect sensitive components.

How to Choose the Right Micro Wire Mesh for Your System

Selecting the Right Aperture Size

Match the mesh opening size to the particle retention requirement. For sub-micron filtering, consider Dutch weave patterns that increase flow and strength.

Material Choice: Stainless Steel, Nickel, or Monel

- Stainless steel: Excellent for general use

- Nickel: Better for high-temperature or caustic environments

- Monel: Best for saltwater or marine filtration

Weave Patterns: Plain, Twilled, or Dutch Weave

- Plain weave: Uniform filtration and good flow

- Twilled weave: Higher strength, lower flexibility

- Dutch weave: High-density filtration with tight pores

✅ Conclusion

Micro wire mesh is revolutionizing filtration system design across multiple industries by delivering precision and durability in a flexible form. Whether you need ultra-fine liquid separation or high-purity air filtration, choosing the right micro wire mesh for filtration systems will ensure efficiency, longevity, and reliability. Contact our technical team today for assistance in selecting the best mesh for your application.