Stainless Steel Mesh Filters in Water Treatment Plants: Proven Industrial Use

Stainless steel mesh filters in water treatment plants have become a trusted solution,

offering strength, corrosion resistance, and long-term cost savings compared to disposable filter media.

This article explores real applications and a case study from municipal water treatment.

Why Stainless Steel Mesh Filters Are Used in Water Treatment

Durability and Corrosion Resistance

Water treatment environments often involve continuous flow, exposure to chemicals like chlorine, and abrasive particles.

Stainless steel mesh withstands these conditions without degrading, unlike synthetic filters.

High Filtration Precision

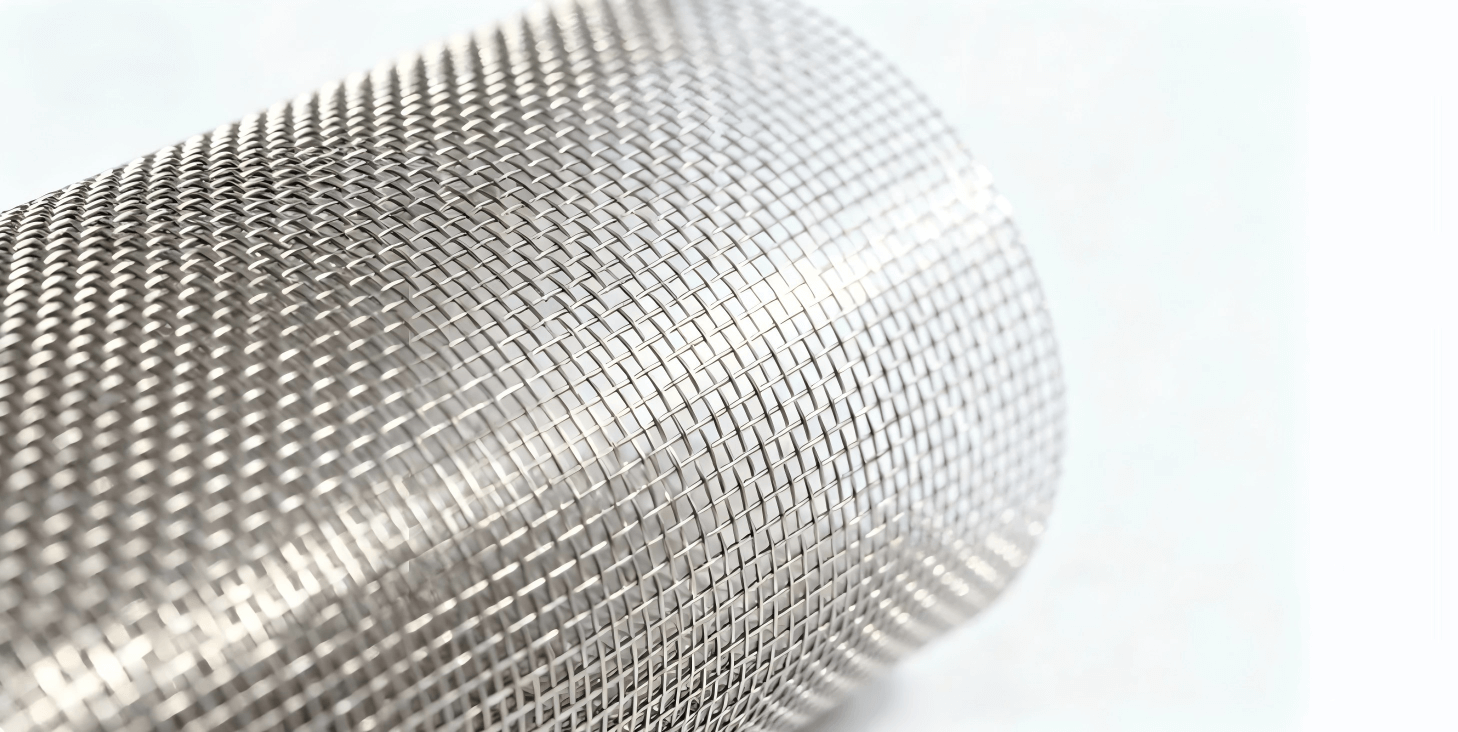

With mesh openings as small as 25 microns, stainless steel filters ensure removal of fine suspended solids,

protecting downstream processes such as reverse osmosis and UV disinfection.

Reusability and Cost Efficiency

Mesh filters can be cleaned and reused multiple times, reducing replacement costs and minimizing waste,

aligning with sustainability goals in water treatment facilities.

Real Case Study: Stainless Steel Mesh Filters in Municipal Water Treatment

The Challenge

A municipal water treatment plant in California experienced frequent clogging of polymer cartridge filters

when treating surface water with high levels of suspended solids.

Maintenance shutdowns occurred every two weeks, impacting plant efficiency.

The Solution

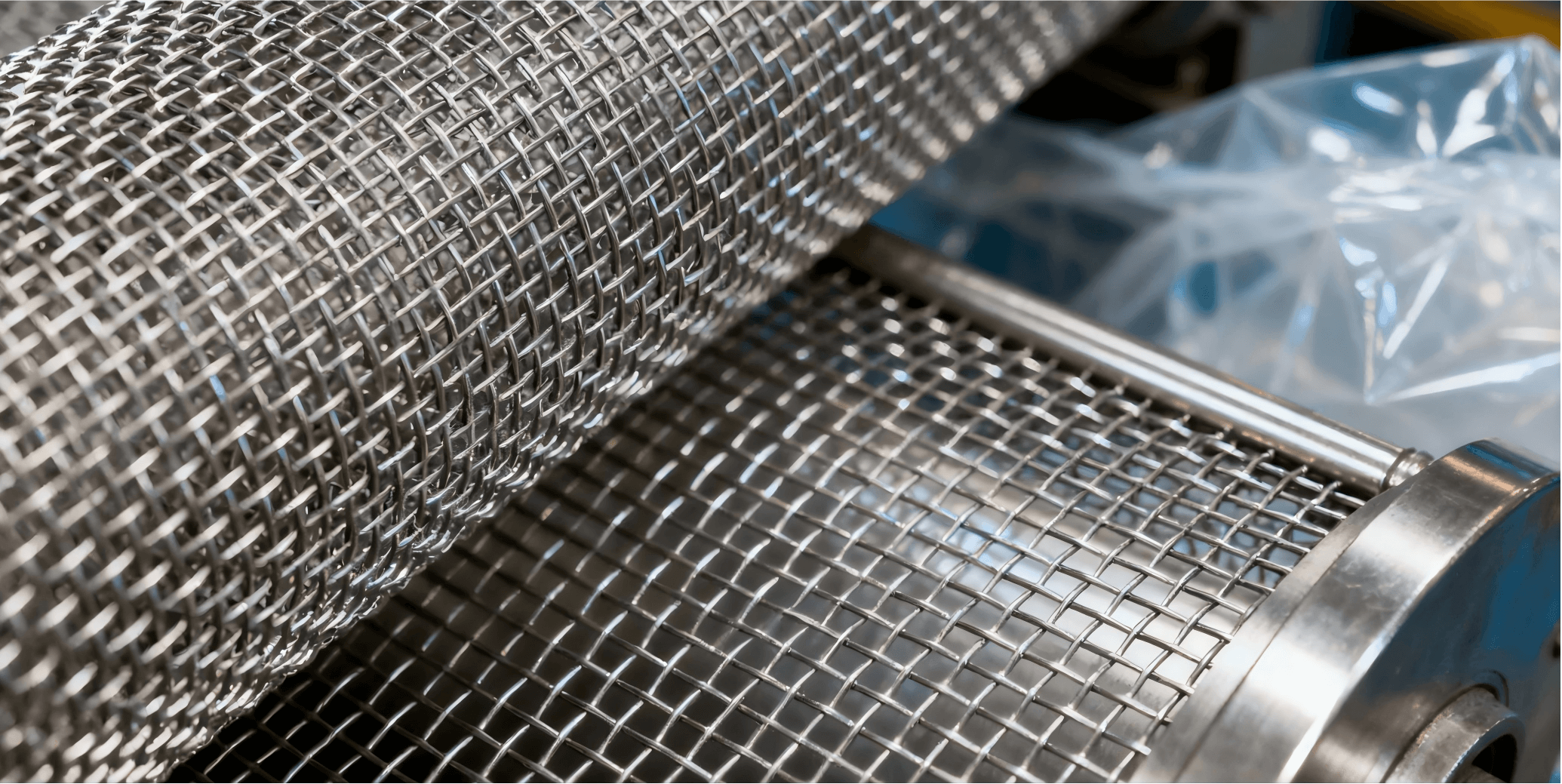

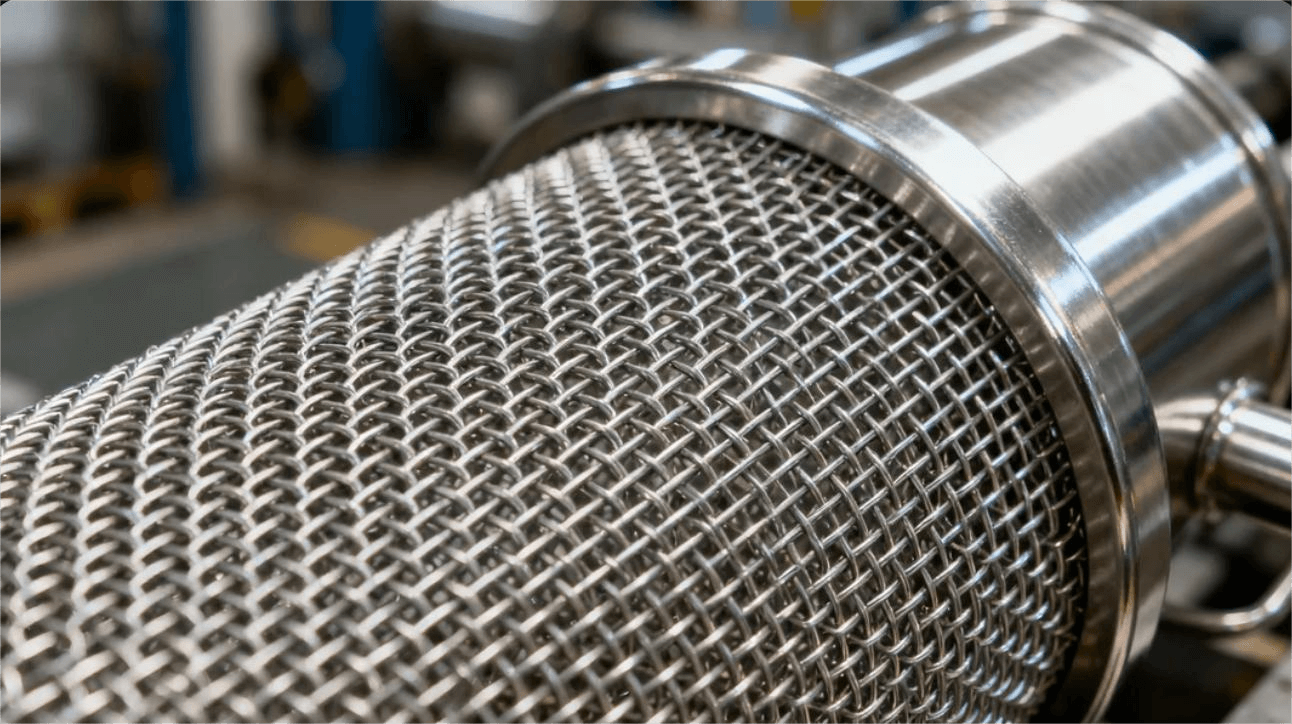

The facility installed 316 stainless steel mesh filters in their pre-filtration units.

The filters were designed with a 50-micron opening and pleated configuration to increase surface area.

The Results

- Extended service life: Filters lasted over 9 months before replacement, compared to 2 weeks for polymer cartridges.

- Reduced operating costs: Annual filter costs were reduced by 65%.

- Improved system reliability: Plant maintenance cycles decreased significantly, improving uptime.

How to Choose Stainless Steel Mesh Filters for Water Treatment

Selecting the Right Mesh Opening

Pre-filtration usually requires mesh sizes between 25–100 microns, while finer polishing filters may use even smaller apertures.

Material Selection: 304 vs. 316 Stainless Steel

While 304 stainless steel is suitable for general water treatment,

316 stainless steel is recommended for facilities using chlorine or treating brackish water.

Filter Configurations

Stainless steel mesh can be fabricated into discs, pleated cartridges, or basket filters,

depending on flow requirements and installation needs.

Conclusion

The case study demonstrates that stainless steel mesh filters in water treatment plants

deliver long-term reliability, cost savings, and environmental benefits.

As sustainability and efficiency become priorities in municipal and industrial water treatment,

stainless steel mesh proves to be an essential filtration solution.

Contact us today to learn more about custom filtration solutions.