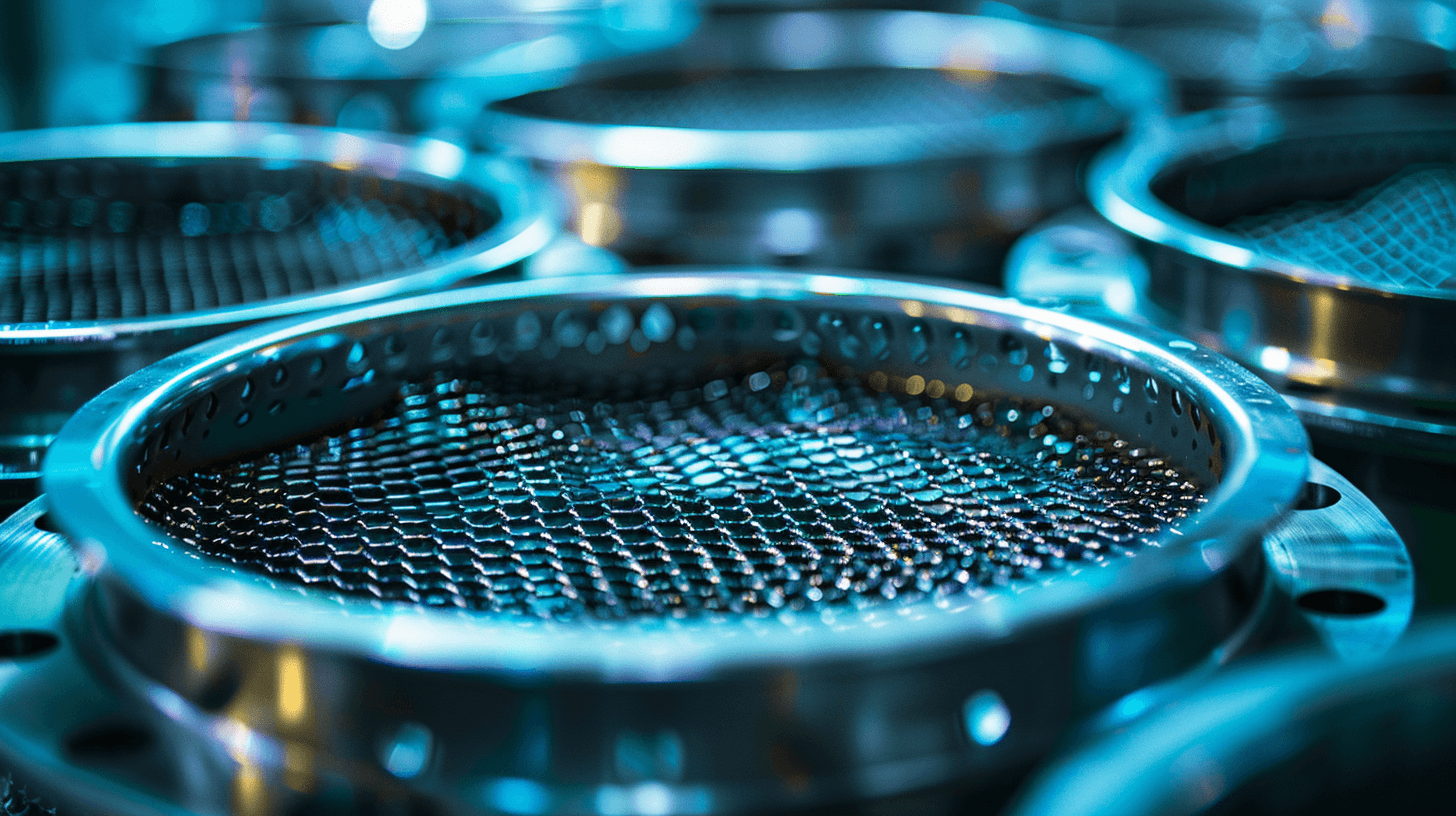

Stainless Steel Wire Mesh Filters for Oil and Gas Industry: Real Refinery Application

Filtration is a critical part of oil and gas production, ensuring that fluids remain clean and free from

particulates that could damage downstream equipment.

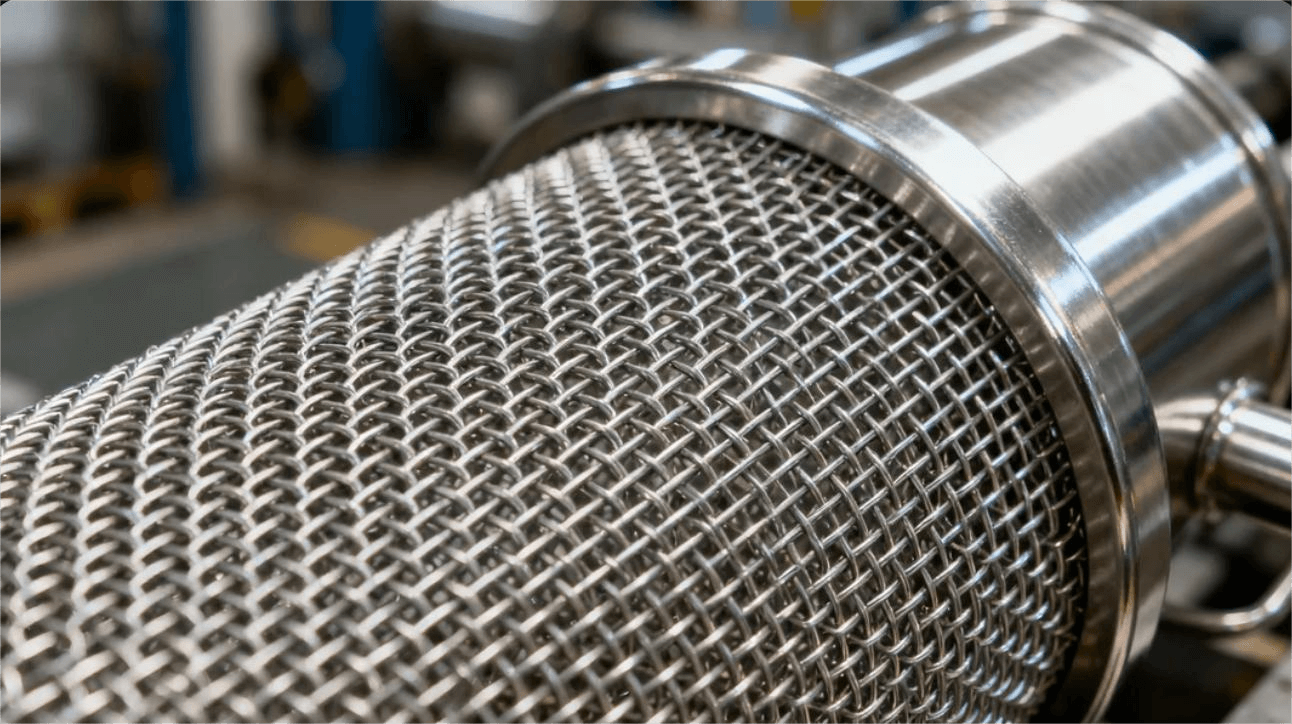

Stainless steel wire mesh filters for oil and gas industry applications are widely used in

separation units, refining processes, and drilling operations due to their superior strength and corrosion resistance.

This article presents a real case study from an oil refinery in Saudi Arabia where stainless steel mesh replaced

synthetic filters in crude oil pre-treatment.

Why the Oil and Gas Industry Uses Stainless Steel Wire Mesh Filters

Extreme Corrosion and Pressure Resistance

Oil refineries and gas plants handle fluids that are often hot, acidic, and corrosive.

Stainless steel wire mesh—especially grades 316L and 904L—resists corrosion from sulfur compounds

and high-pressure environments, outperforming polymer and carbon steel filters.

High Filtration Efficiency

Wire mesh filters can be woven to precise openings (from 5 to 500 microns), allowing efficient removal of solid

contaminants from hydrocarbons, lubricants, and natural gas streams.

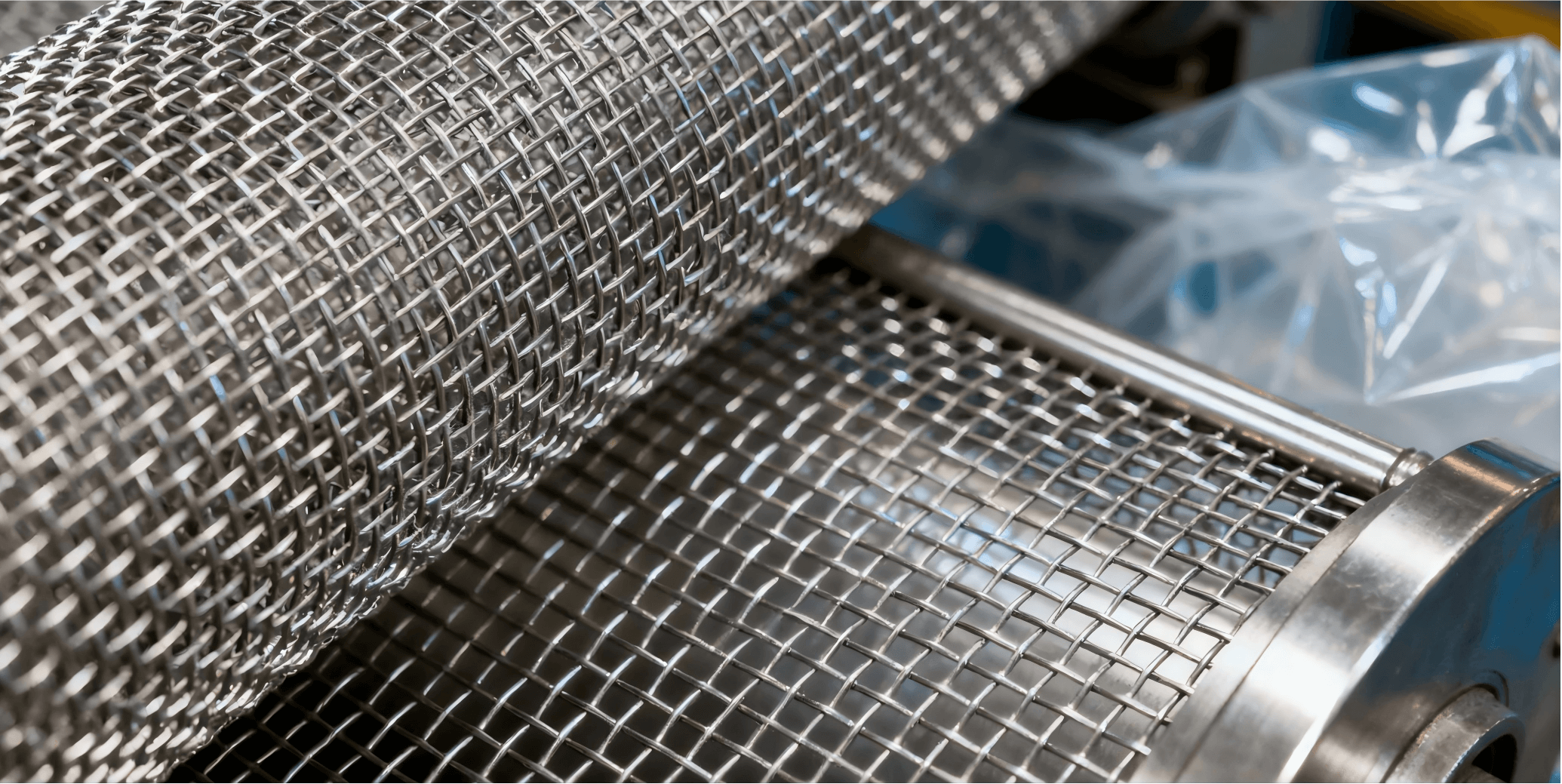

Longevity and Reusability

Unlike disposable cartridges, stainless steel filters can be cleaned and reused through backflushing,

reducing replacement frequency and operational waste.

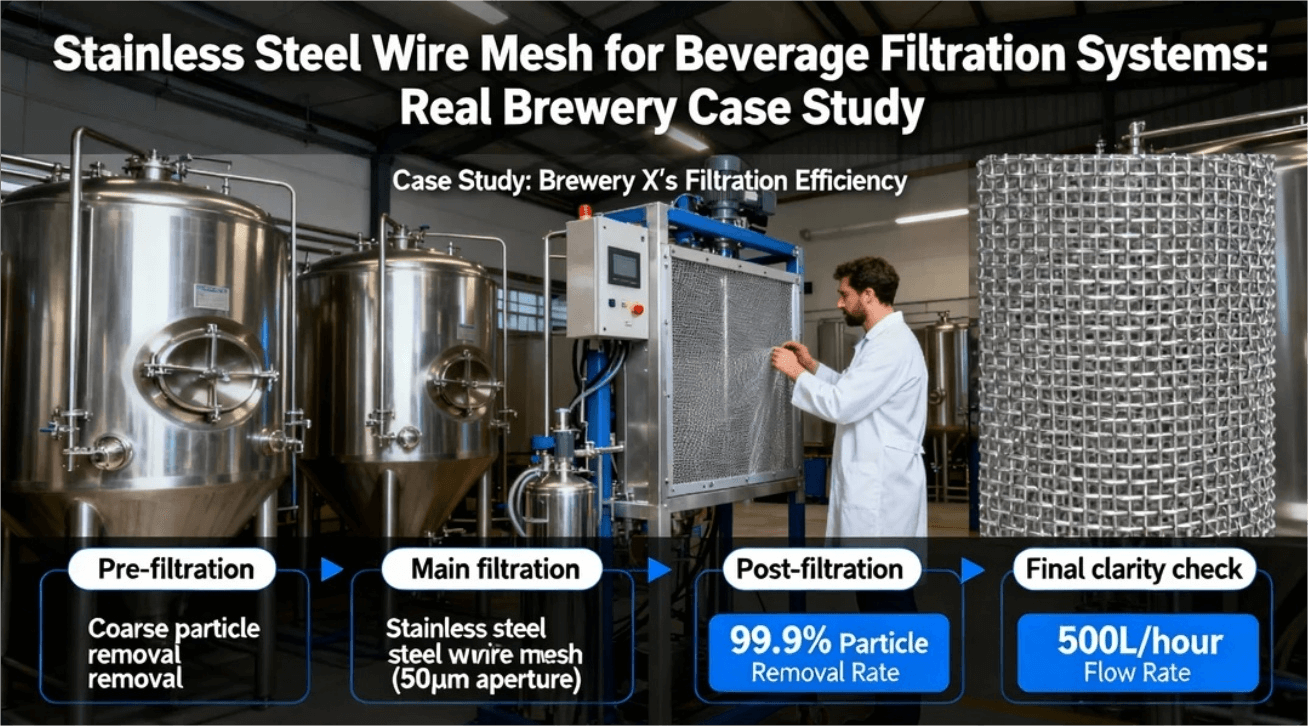

Real Case Study: Crude Oil Pre-Filtration at a Saudi Refinery

The Background

A major Saudi refinery processing over 300,000 barrels per day experienced premature clogging of

polymer filters used in crude oil pre-filtration. Frequent filter changes caused production interruptions

and increased maintenance costs.

The Solution

The refinery partnered with an industrial filtration supplier to install

316L stainless steel wire mesh filters with 50-micron apertures.

These were integrated into the pre-treatment unit upstream of the distillation tower.

The Results

- Filter lifespan: Increased from 10 days to over 6 months.

- Maintenance costs: Reduced by 65%.

- System uptime: Improved by 40% with fewer shutdowns.

- Operational reliability: Filters maintained stable flow and pressure drop over multiple cleaning cycles.

Other Oil & Gas Applications for Stainless Steel Mesh

Natural Gas Filtration

Stainless steel mesh removes dust, rust, and solid particles in natural gas compressor stations and dehydration units.

Lube Oil and Hydraulic Fluid Filtration

Wire mesh filters protect turbines, pumps, and hydraulic systems by capturing metallic debris and impurities

in circulating lubricants.

Produced Water Treatment

In offshore operations, stainless steel mesh is used in separation systems to filter oil droplets and

suspended solids before water disposal or reinjection.

Conclusion

The Saudi refinery case study demonstrates how

stainless steel wire mesh filters for oil and gas industry

provide superior durability, corrosion resistance, and cost-effectiveness

compared to traditional filter media. Their reliability under extreme conditions makes them

essential for both onshore and offshore filtration systems.

Contact our team to learn more about custom stainless steel mesh filters

designed for oil and gas operations.