Stainless Steel Wire Mesh Filters in the Pharmaceutical Industry: Real Filtration Applications

In the pharmaceutical industry, filtration plays a vital role in maintaining product sterility and purity.

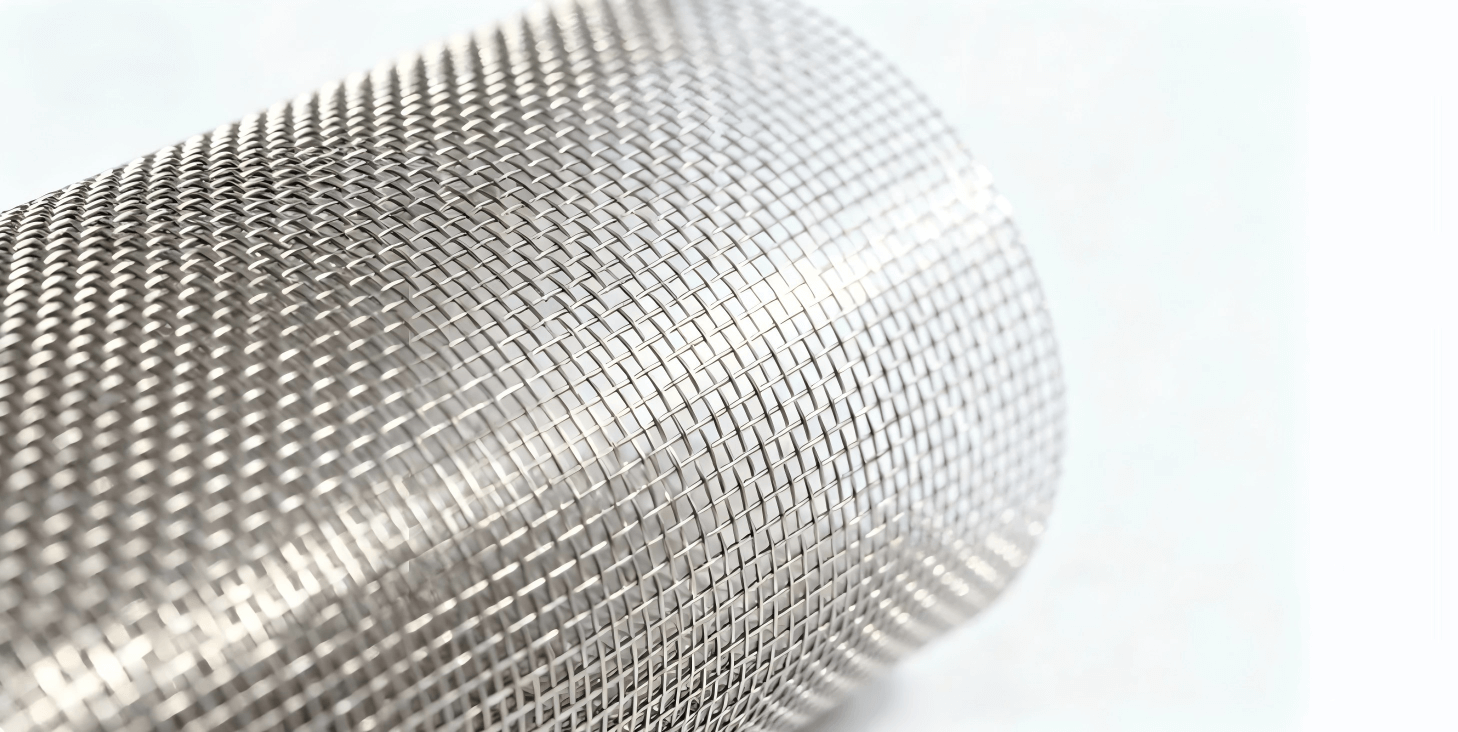

Stainless steel wire mesh filters for pharmaceutical industry applications are preferred for

their precision, durability, and ability to withstand rigorous cleaning and sterilization cycles.

This article explores a real industrial application and explains why stainless steel mesh has become indispensable

in pharmaceutical filtration systems.

Why Stainless Steel Mesh Filters Are Ideal for Pharmaceutical Filtration

Durability and Reusability

Pharmaceutical processing requires filters that can endure repeated sterilization through autoclaving or chemical

cleaning. Stainless steel wire mesh is resistant to high temperatures and corrosive cleaning agents, allowing

for multiple reuse cycles without losing filtration efficiency.

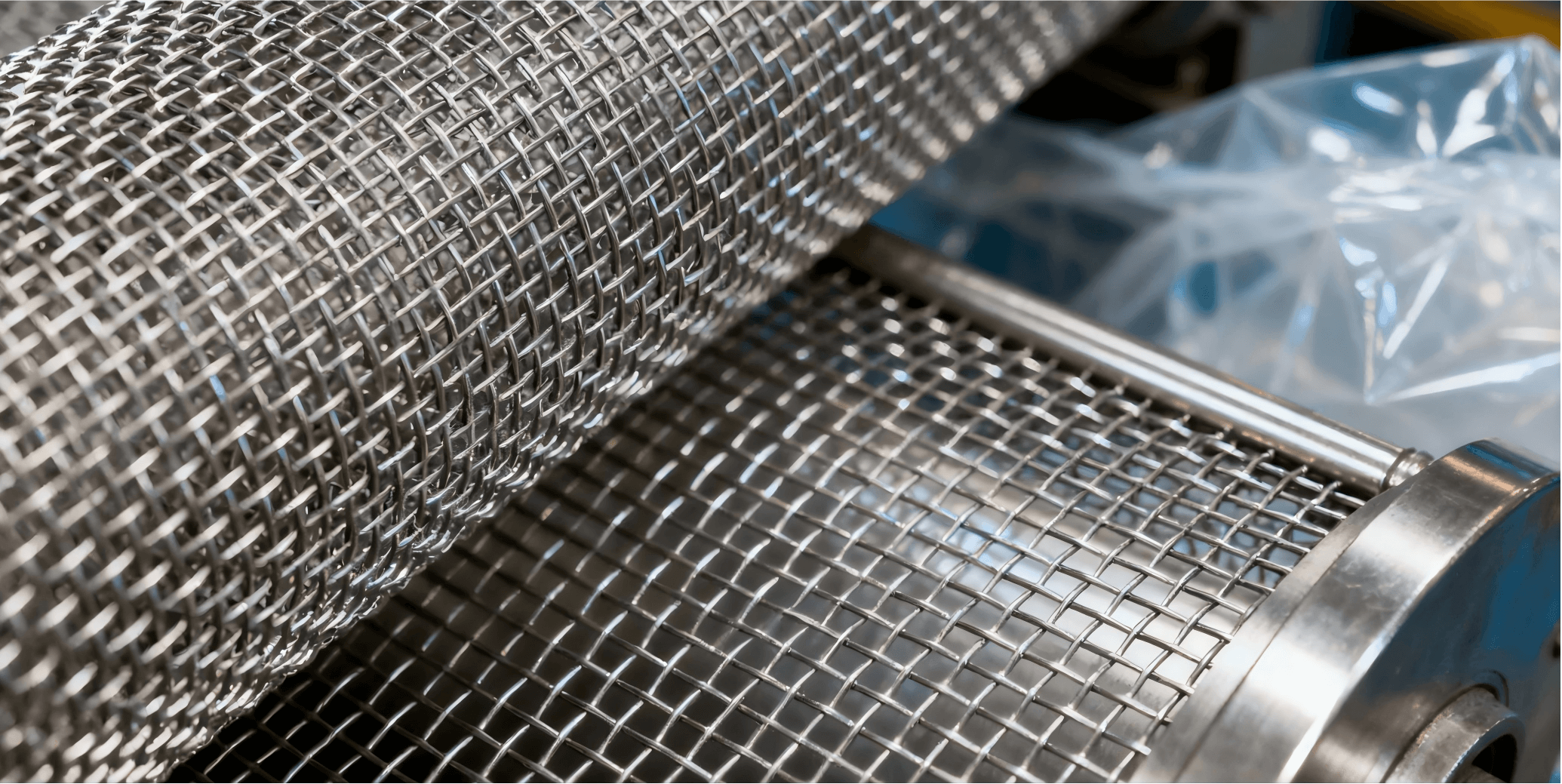

Precision Filtration

Stainless steel meshes can be woven with micron-level accuracy (5–500 µm), ensuring consistent particle

retention for both liquid and gas filtration stages in drug production.

Regulatory Compliance

In compliance with FDA and GMP standards, stainless steel filters are non-shedding,

non-reactive, and easy to clean—making them ideal for sterile drug manufacturing.

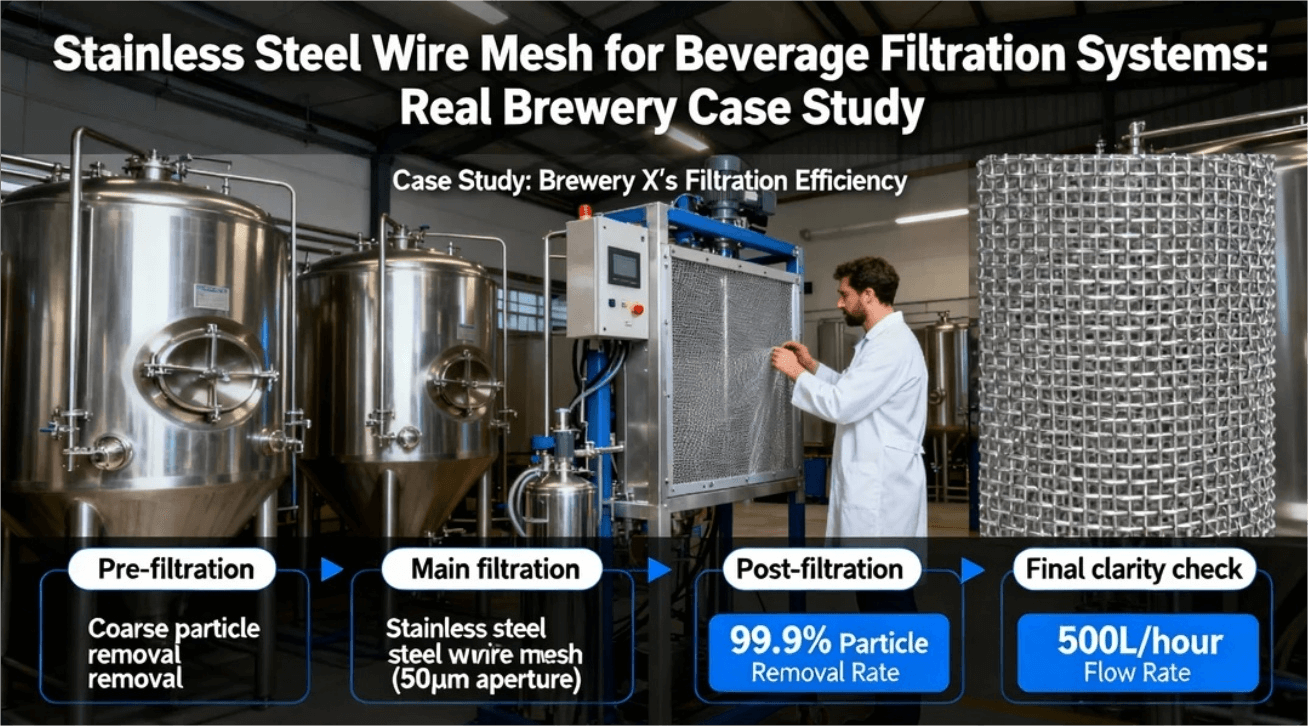

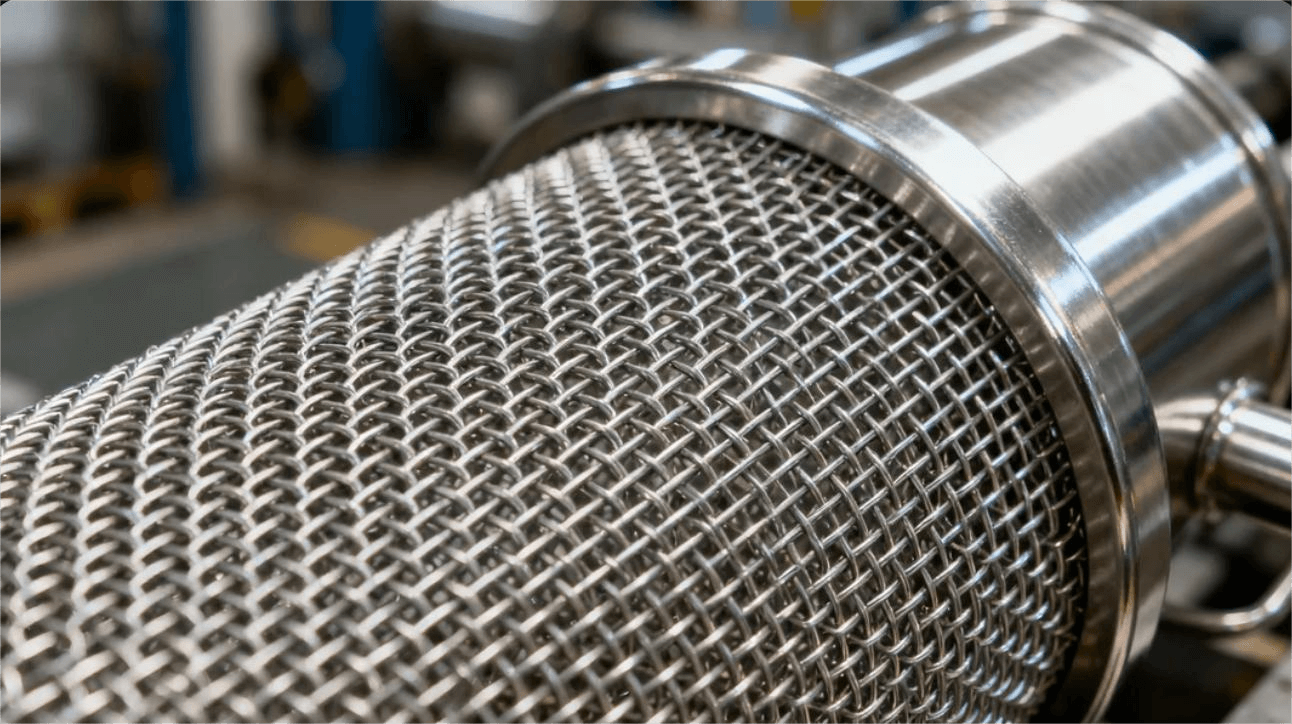

Real Case Study: Sterile Filtration at a European Pharmaceutical Plant

The Background

A major European pharmaceutical manufacturer producing intravenous (IV) solutions and vaccines

faced recurring issues with polymer cartridge filters—frequent clogging, inconsistent flow,

and material shedding during sterilization.

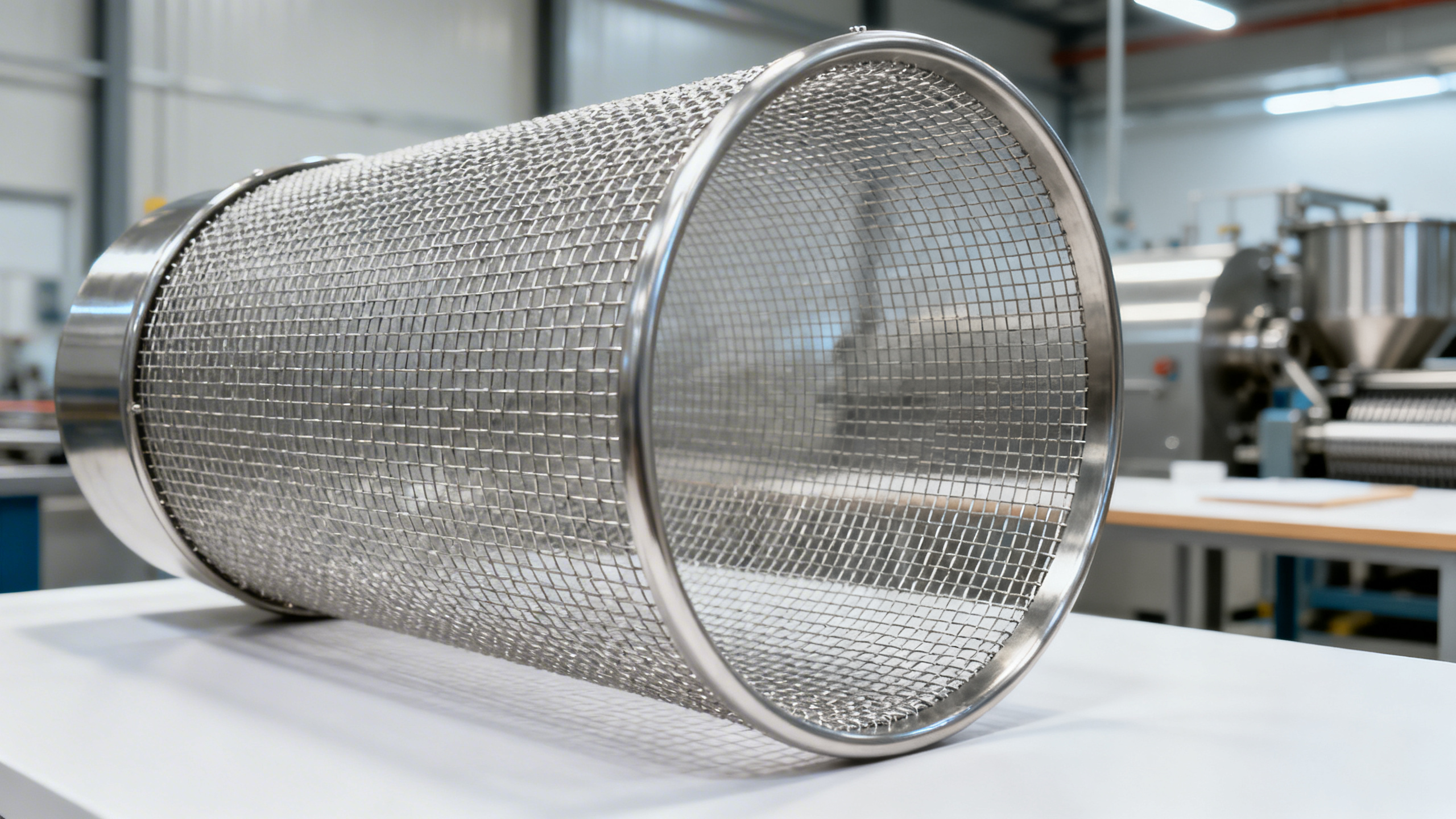

The Solution

The company upgraded to 316L stainless steel wire mesh filters with a 25-micron aperture,

integrated into their liquid sterilization system. The mesh filters were installed at multiple stages:

pre-filtration, sterile filtration, and final polishing.

The Results

- Filter lifespan: Extended from 2 weeks to over 10 months.

- Reduced downtime: Maintenance intervals decreased by 70%.

- Improved sterility assurance: No fiber contamination detected in QC testing.

- Lower operational cost: Reusable filters reduced consumable expenses by 60%.

Applications of Wire Mesh Filters in Pharma Manufacturing

Liquid Filtration

Used in filtration of APIs (Active Pharmaceutical Ingredients), sterile water, and buffer solutions

to remove particulates before downstream purification.

Air and Gas Filtration

Stainless steel mesh serves as pre-filters in cleanroom HVAC systems, ensuring that air entering

production areas remains contaminant-free.

Powder Handling and Drying

In powder processing, wire mesh filters control airborne particulate release during drying and blending operations.

Conclusion

The case study clearly demonstrates how stainless steel wire mesh filters for pharmaceutical industry

applications enhance production reliability, sterility, and long-term cost efficiency.

Their ability to meet strict regulatory standards while providing superior filtration performance

makes them a top choice for pharmaceutical filtration systems.

Contact our team to learn how stainless steel mesh can optimize your filtration processes.