Stainless Steel Wire Mesh for Flexographic Ink Filtration in Flexible Packaging

In the flexible packaging industry, print quality is directly linked to ink cleanliness.

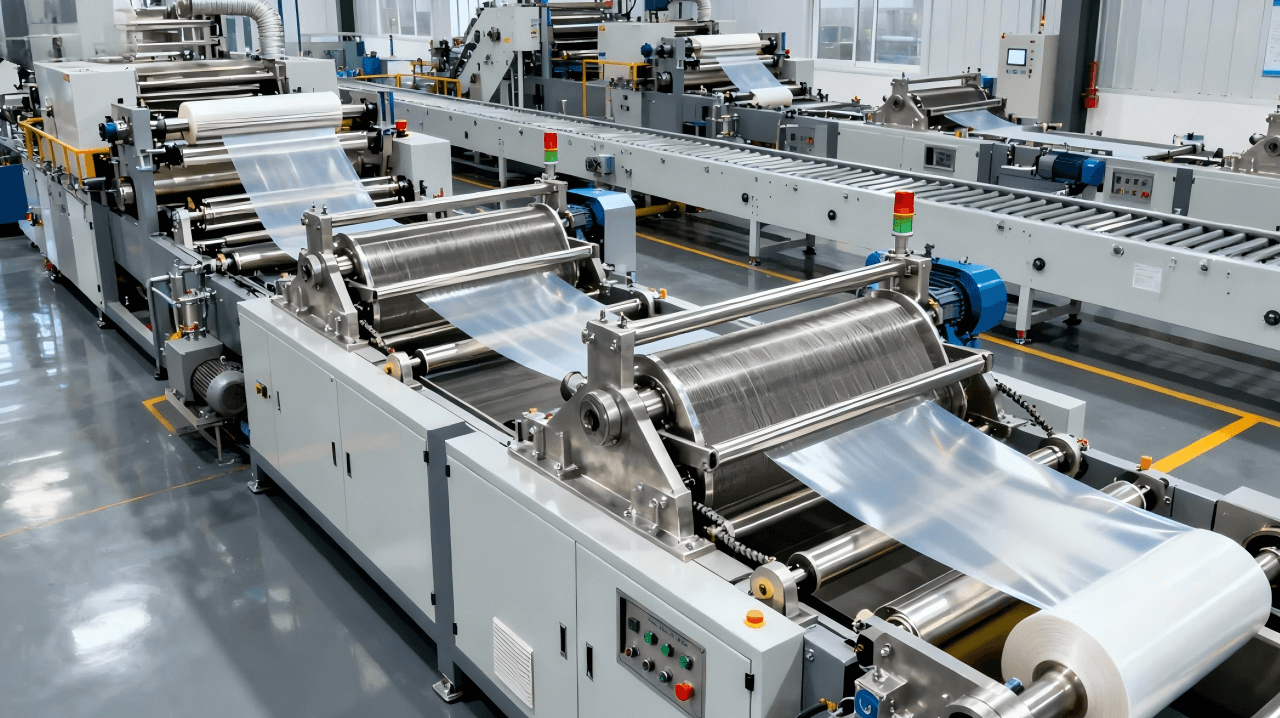

A stainless steel wire mesh for flexographic ink filtration in flexible packaging

is widely used to remove impurities from inks before they reach the printing unit.

This article explains how stainless steel wire mesh is applied in real packaging printing operations

and presents an industry-proven flexographic printing case.

Why Ink Filtration Is Critical in Flexible Packaging Printing

Flexible packaging relies heavily on flexographic printing to apply graphics,

branding, and regulatory information on plastic films.

Printing inks may contain:

- Dried ink particles

- Pigment agglomerates

- Dust and foreign contaminants

Without proper filtration, these contaminants can block anilox cells,

damage doctor blades, and cause print defects such as pinholes and streaking.

Why Stainless Steel Wire Mesh Is Used for Ink Filtration

Chemical Resistance to Printing Inks

Stainless steel wire mesh is compatible with water-based,

solvent-based, and UV flexographic inks.

It does not react with ink components and does not release fibers into the ink system.

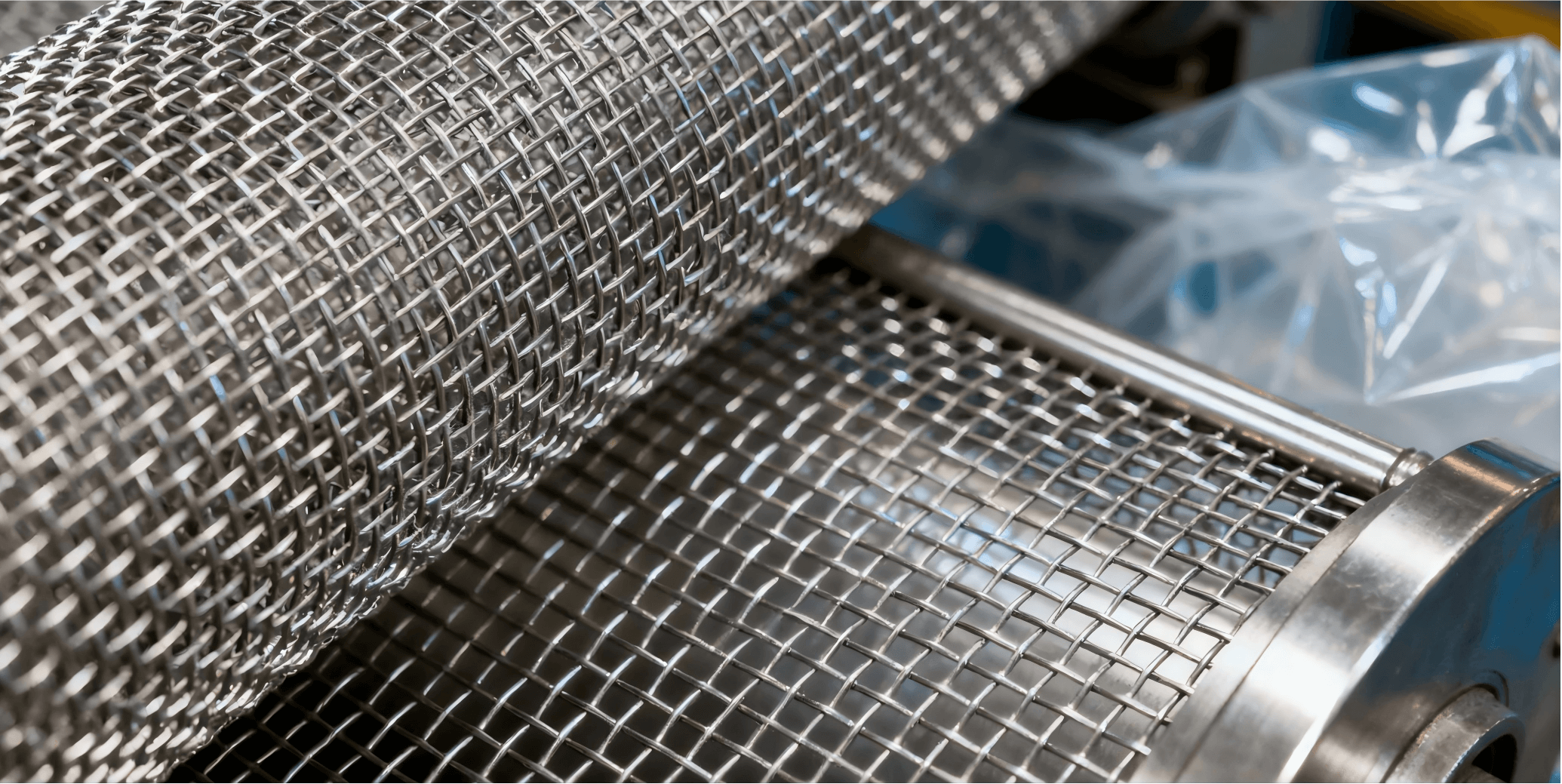

Stable and Uniform Filtration

Wire mesh provides consistent pore sizes,

typically ranging from 25 to 150 microns,

allowing effective removal of contaminants without restricting ink flow.

Protection of Printing Components

Ink filtration using stainless steel mesh protects

anilox rollers and doctor blade systems,

extending their service life and reducing maintenance costs.

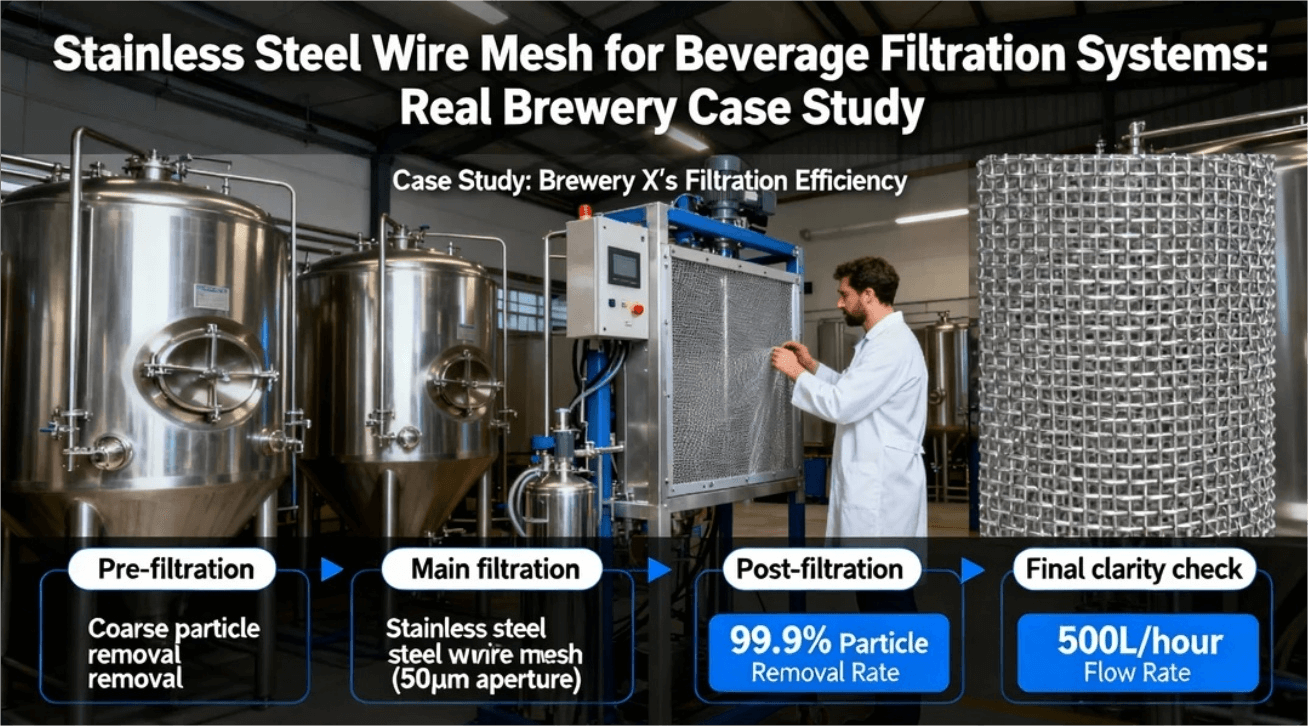

Real Industry Case: Flexographic Printing Line for Flexible Packaging

Production Background

A flexible packaging manufacturer in India operates multiple flexographic printing lines

producing printed films for snack and food packaging.

The inks used include water-based and solvent-based formulations.

Ink Filtration Challenge

The printing lines experienced frequent anilox clogging

and visible print defects caused by ink contamination during long production runs.

This resulted in machine stoppages and increased waste.

Implemented Filtration Solution

The manufacturer installed stainless steel wire mesh ink filters

with a 75-micron aperture in the ink circulation system,

upstream of the printing units.

The mesh filters were housed in stainless steel filter assemblies

and cleaned regularly as part of scheduled press maintenance.

Observed Results

- Reduction in print defects such as streaks and pinholes

- More stable ink flow during extended print runs

- Reduced anilox roller cleaning frequency

- Lower ink waste and improved production efficiency

Other Printing Applications of Stainless Steel Wire Mesh

Gravure Printing Ink Filtration

Wire mesh filtration is also used in gravure printing

to protect engraved cylinders from particle damage.

Ink Mixing and Preparation Systems

Stainless steel mesh filters remove contaminants

before inks enter the main circulation loop.

Coating and Varnish Filtration

Mesh filters ensure clean application of overprint varnishes

and functional coatings in flexible packaging.

Frequently Asked Questions

What mesh size is typically used for flexographic ink filtration?

Most flexographic printing applications use stainless steel wire mesh

between 50 and 100 microns, depending on ink type and anilox specifications.

Can stainless steel wire mesh be reused for ink filtration?

Yes. Stainless steel mesh filters can be cleaned and reused,

making them suitable for continuous industrial printing operations.

Conclusion

This real printing case demonstrates that

stainless steel wire mesh for flexographic ink filtration in flexible packaging

is essential for maintaining print quality,

protecting critical printing components,

and reducing unplanned downtime.

As packaging designs become more complex,

reliable ink filtration remains a key factor in efficient printing operations.

Contact our technical team to select the right stainless steel wire mesh

for your printing ink filtration system.