Stainless Steel Wire Mesh for Oil Filtration in Refineries: Proven Industrial Applications

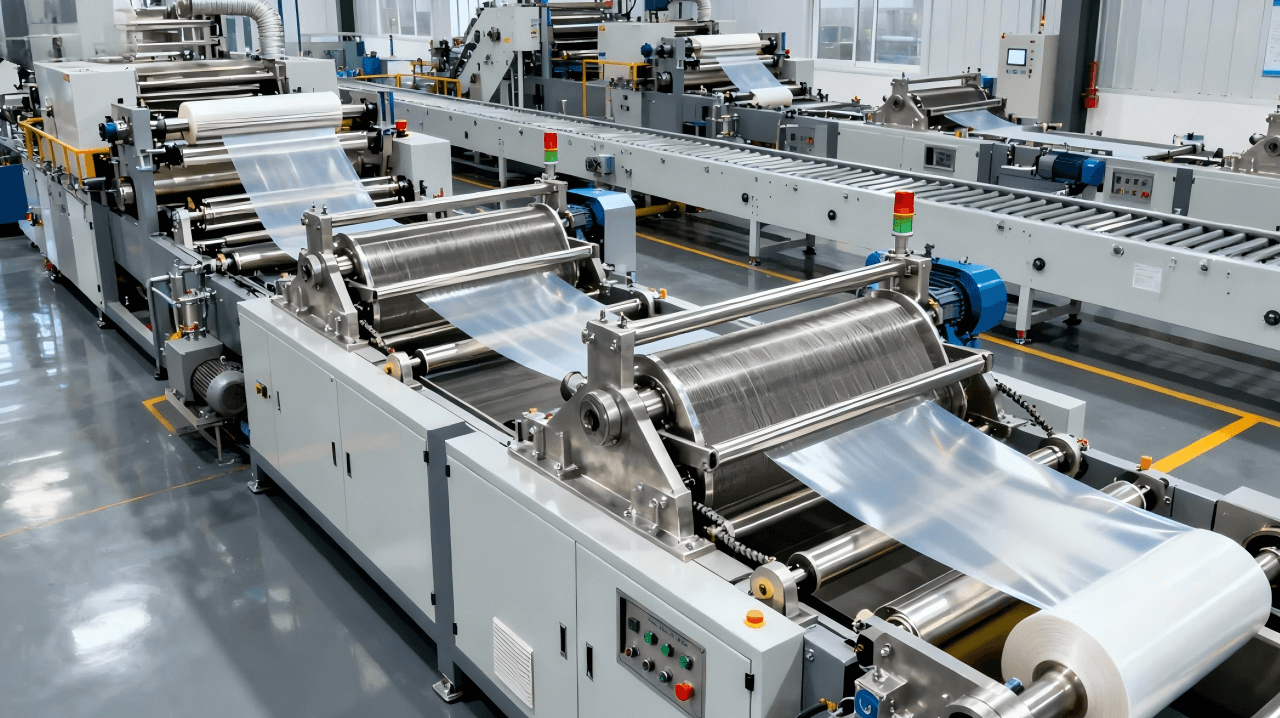

Oil refineries depend on reliable filtration to protect equipment, ensure fuel purity, and extend process efficiency.

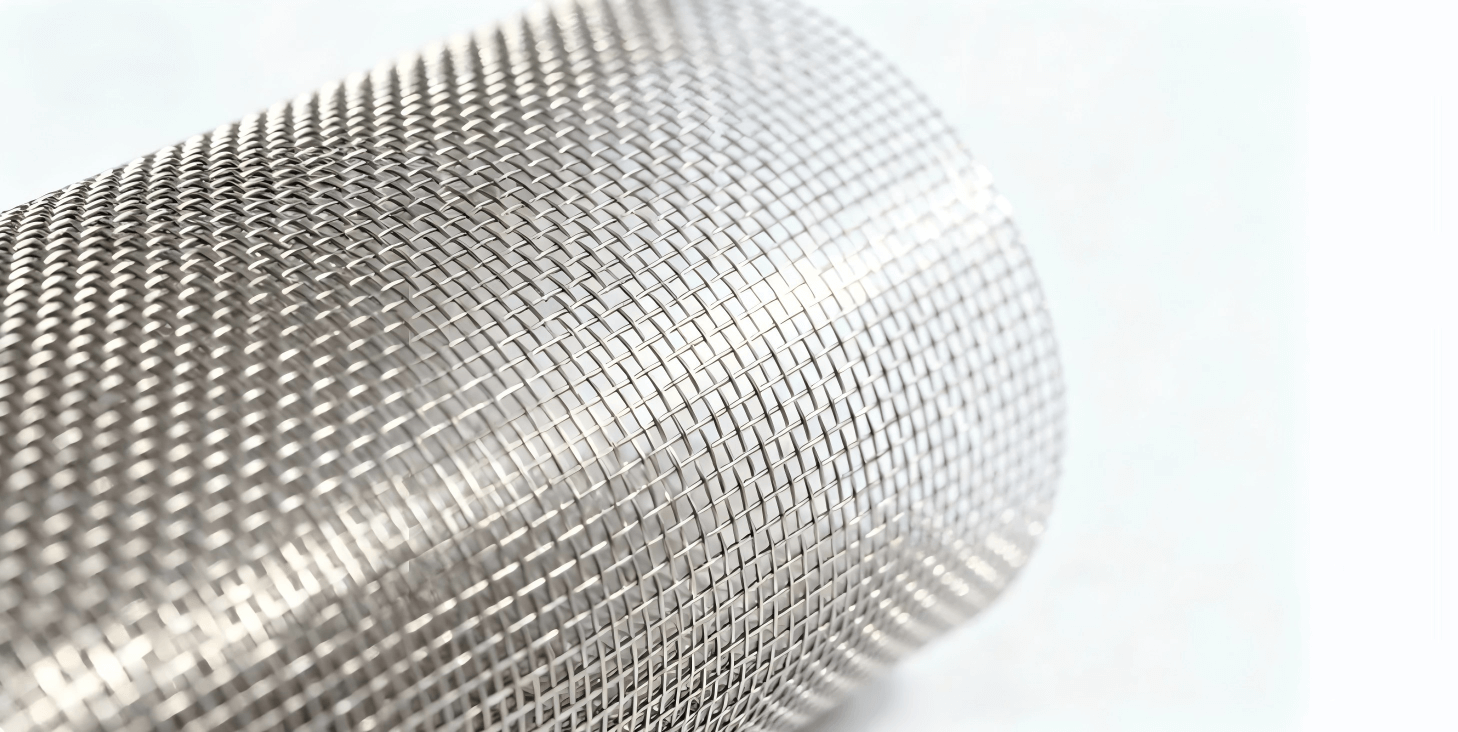

Stainless steel wire mesh for oil filtration in refineries has become a standard due to its high strength,

resistance to heat and chemicals, and long service life. In this article, we will examine its key benefits and highlight

a real-world case study from a Middle Eastern refinery.

Why Oil Refineries Choose Stainless Steel Wire Mesh

High Temperature and Pressure Resistance

Refinery filtration often takes place under extreme conditions. Stainless steel mesh can withstand operating

temperatures above 500°C and pressures common in refining processes.

Compatibility with Hydrocarbons

Stainless steel is non-reactive with crude oil, diesel, lubricants, and additives,

ensuring that filtration does not compromise oil quality.

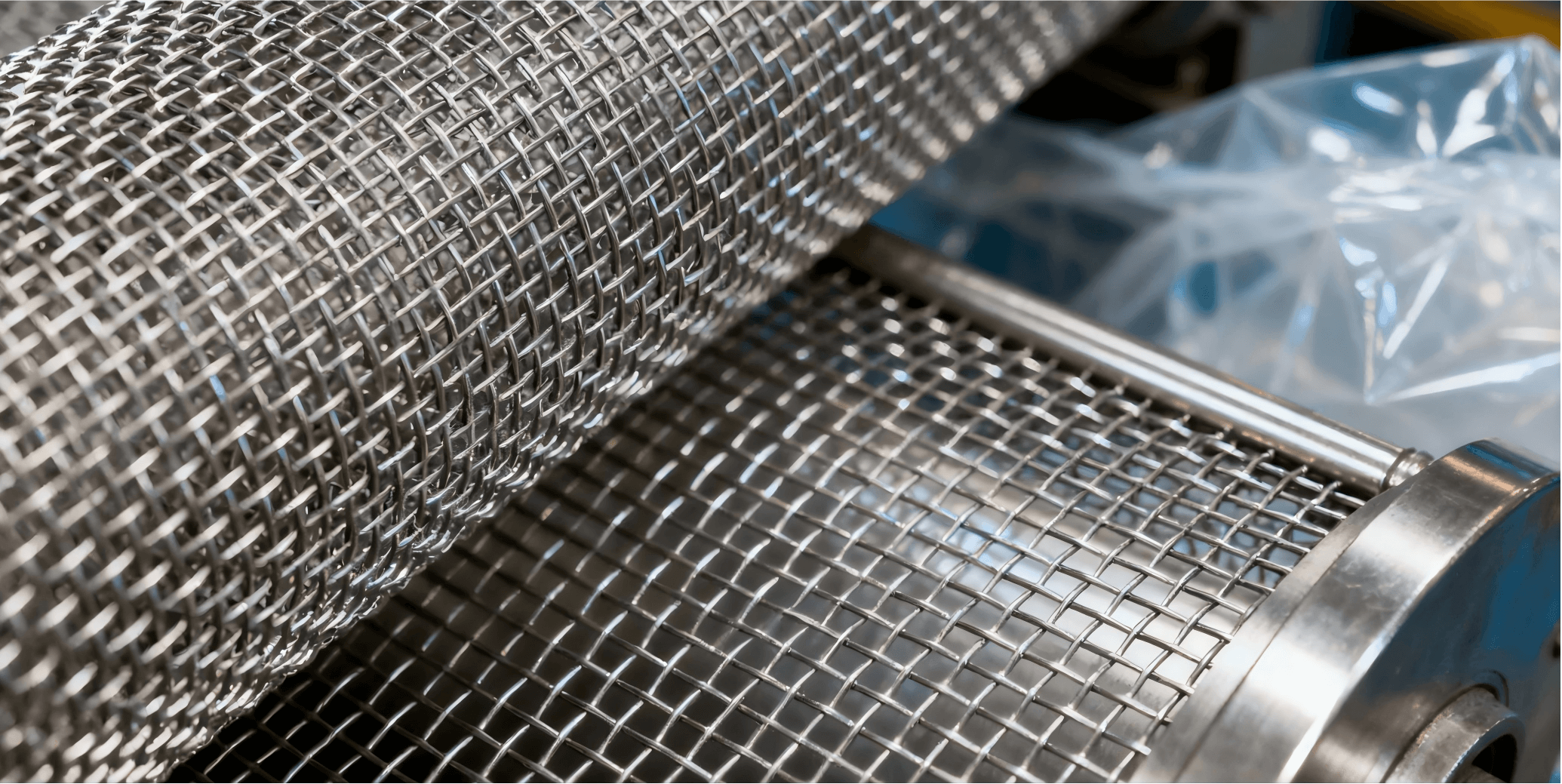

Reusability and Cost Efficiency

Unlike disposable cartridges, stainless steel mesh can be cleaned and reused,

significantly reducing annual filtration costs in large-scale refinery operations.

Real Case Study: Stainless Steel Mesh in a Middle Eastern Refinery

The Challenge

A refinery processing 200,000 barrels of crude oil per day faced frequent clogging of synthetic filter cartridges

in its lube oil system. Filter replacement every two weeks caused high costs and unscheduled downtime.

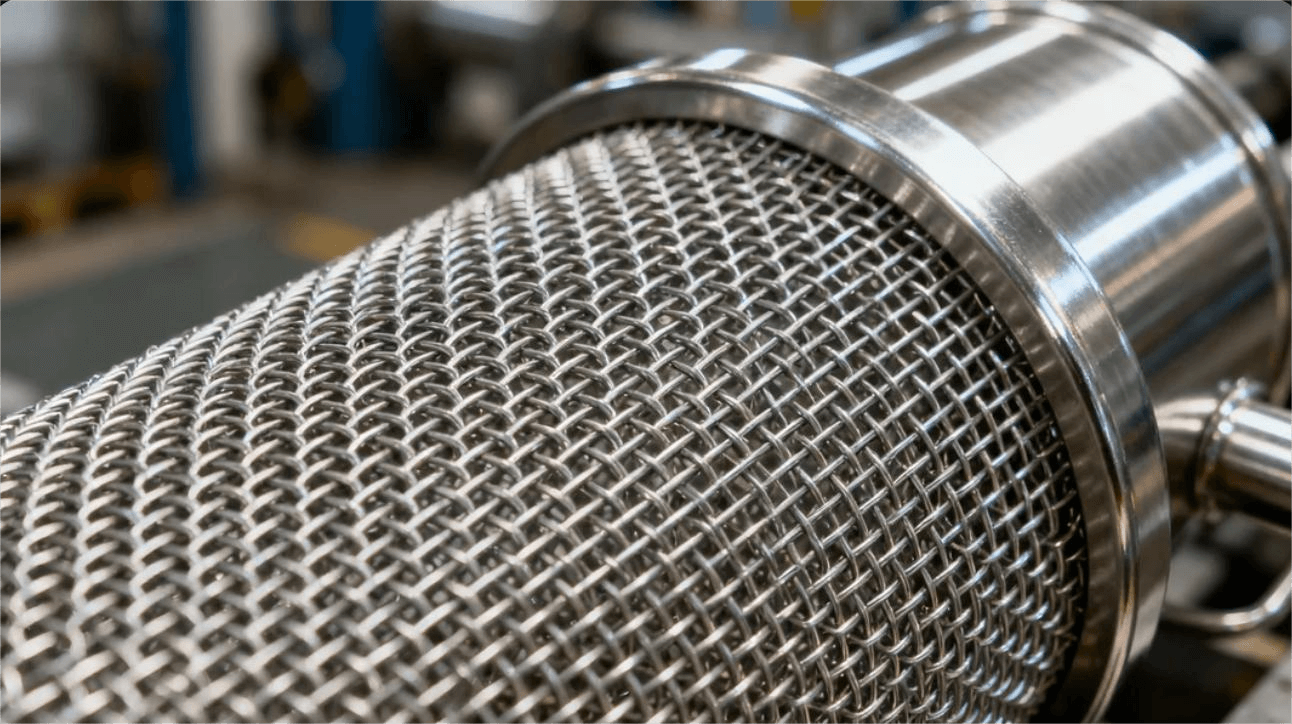

The Solution

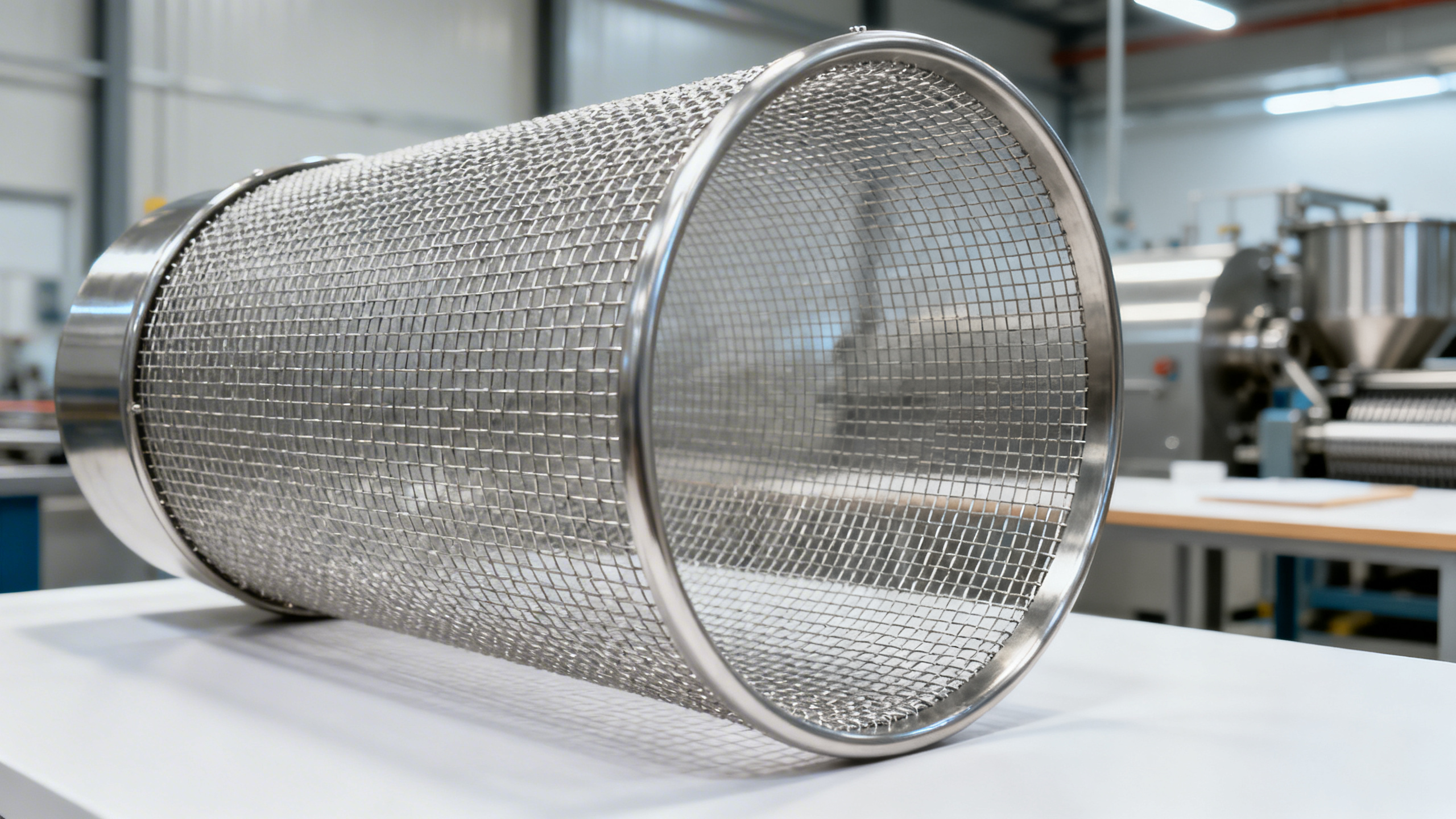

The refinery replaced disposable polymer filters with

316 stainless steel wire mesh filters (25-micron rating).

Custom-designed basket filters were installed in lubrication and hydraulic systems,

capable of withstanding continuous cleaning cycles.

The Results

- Extended filter life: Mesh filters lasted 18 months compared to 2 weeks for polymer cartridges.

- Cost savings: Annual filter expenses reduced by 70%.

- Improved reliability: Lubrication systems operated without unplanned downtime for over a year.

- Environmental benefits: Reduced waste from disposable filters by more than 90%.

How to Select Stainless Steel Mesh for Refinery Oil Filtration

Choosing the Right Micron Rating

Refinery oil filtration typically requires mesh between 10–50 microns, depending on whether the goal is

removing fine particulates, protecting pumps, or polishing product streams.

Material Selection: 304 vs. 316 Stainless Steel

316 stainless steel is generally preferred for refinery applications

due to its superior corrosion resistance against sulfur-containing hydrocarbons.

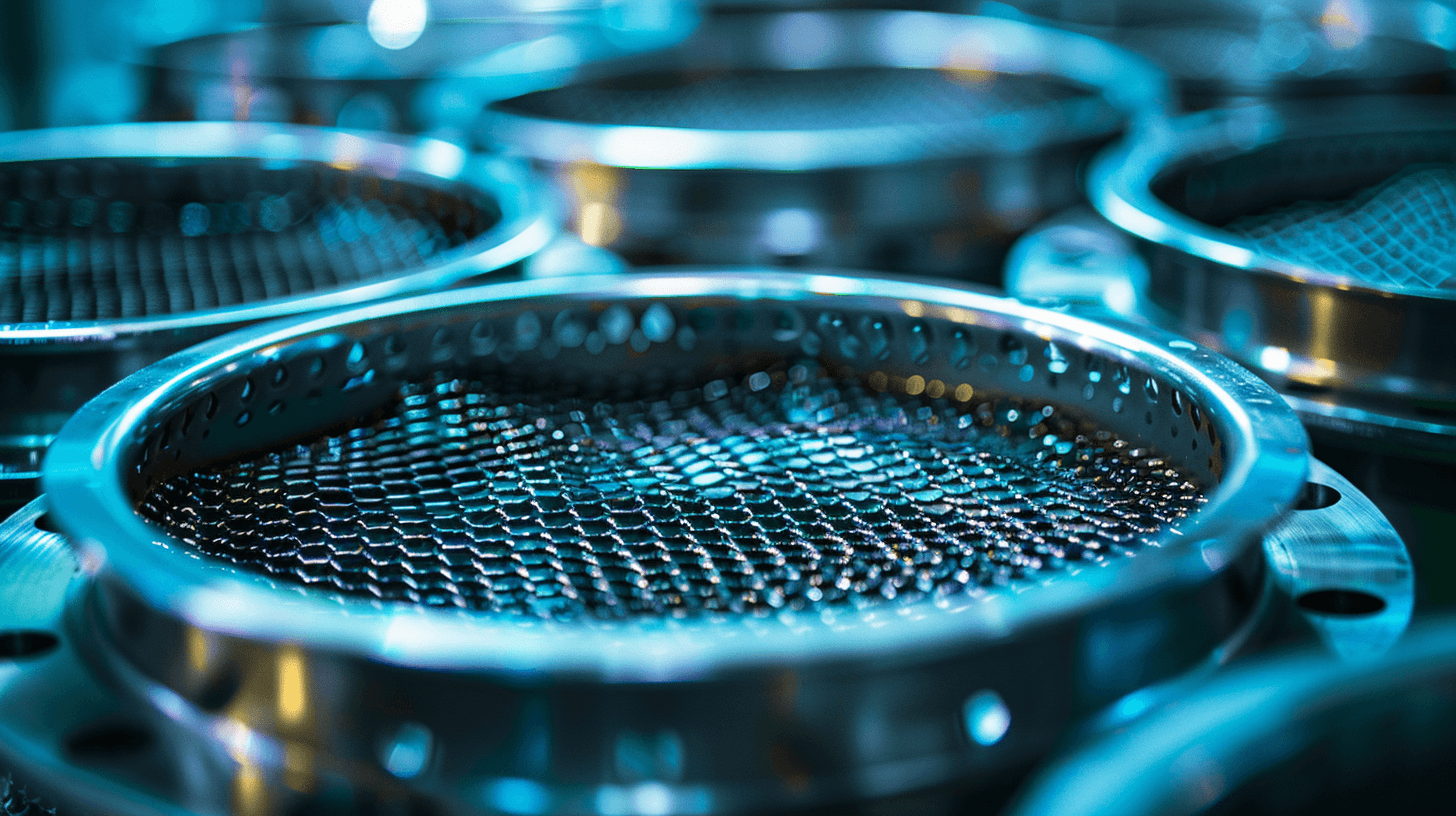

Filter Configurations

Stainless steel mesh can be configured into discs, pleated cartridges, or large basket filters,

depending on system flow rates and installation requirements.

Conclusion

The refinery case study shows that

stainless steel wire mesh for oil filtration in refineries

delivers significant benefits in cost savings, durability, and reliability.

With its proven ability to withstand harsh conditions, stainless steel mesh is a smart choice

for refining operations worldwide.

Contact us today to learn more about custom stainless steel mesh filters for refinery applications.