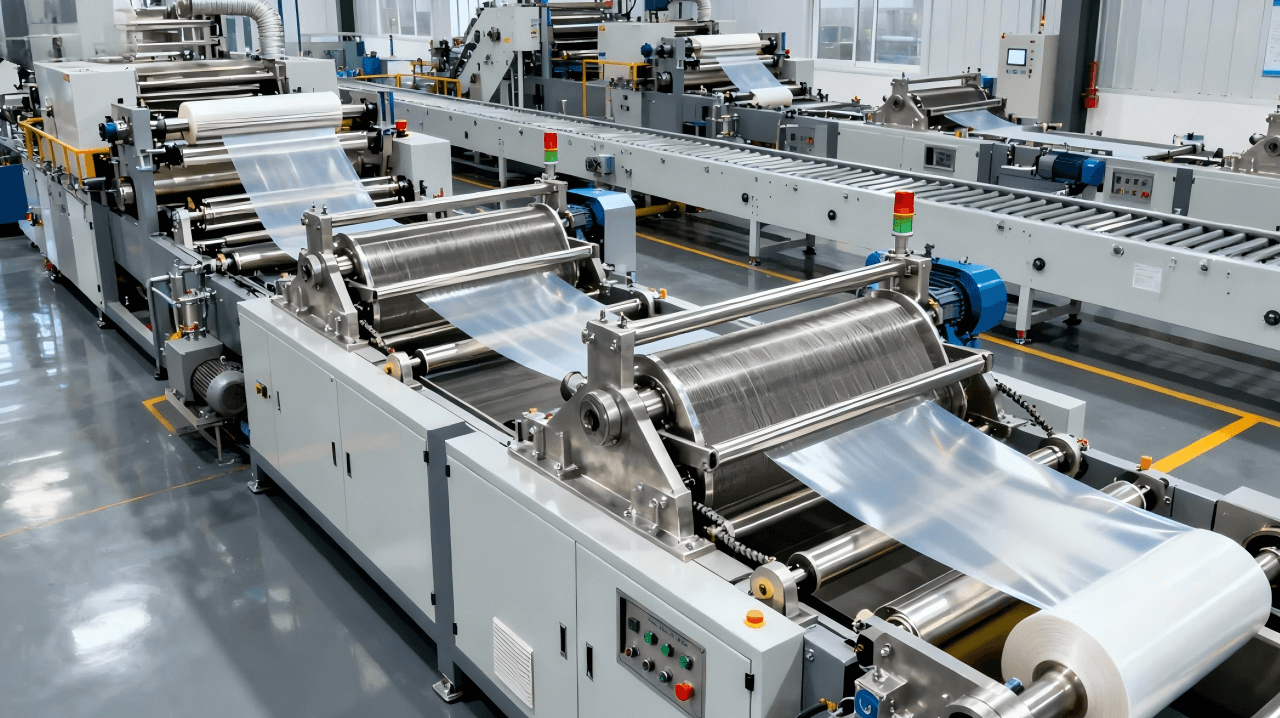

Stainless Steel Wire Mesh for Plastic Extrusion Melt Filtration in Flexible Packaging

In the flexible packaging industry, melt filtration is a critical step in plastic extrusion processes.

Stainless steel wire mesh for plastic extrusion melt filtration is widely used to remove solid contaminants,

gels, and degraded polymer particles before film formation.

This article explains how stainless steel mesh is applied in real flexible packaging production

and presents a proven industrial case from a blown film extrusion line.

What Is Melt Filtration in Flexible Packaging?

Melt filtration is the process of removing impurities from molten polymers such as PE, PP, and PET

during extrusion. In flexible packaging, effective melt filtration ensures:

- Uniform film thickness

- Improved optical clarity

- Reduced die and screen changer blockage

- Lower risk of film breakage

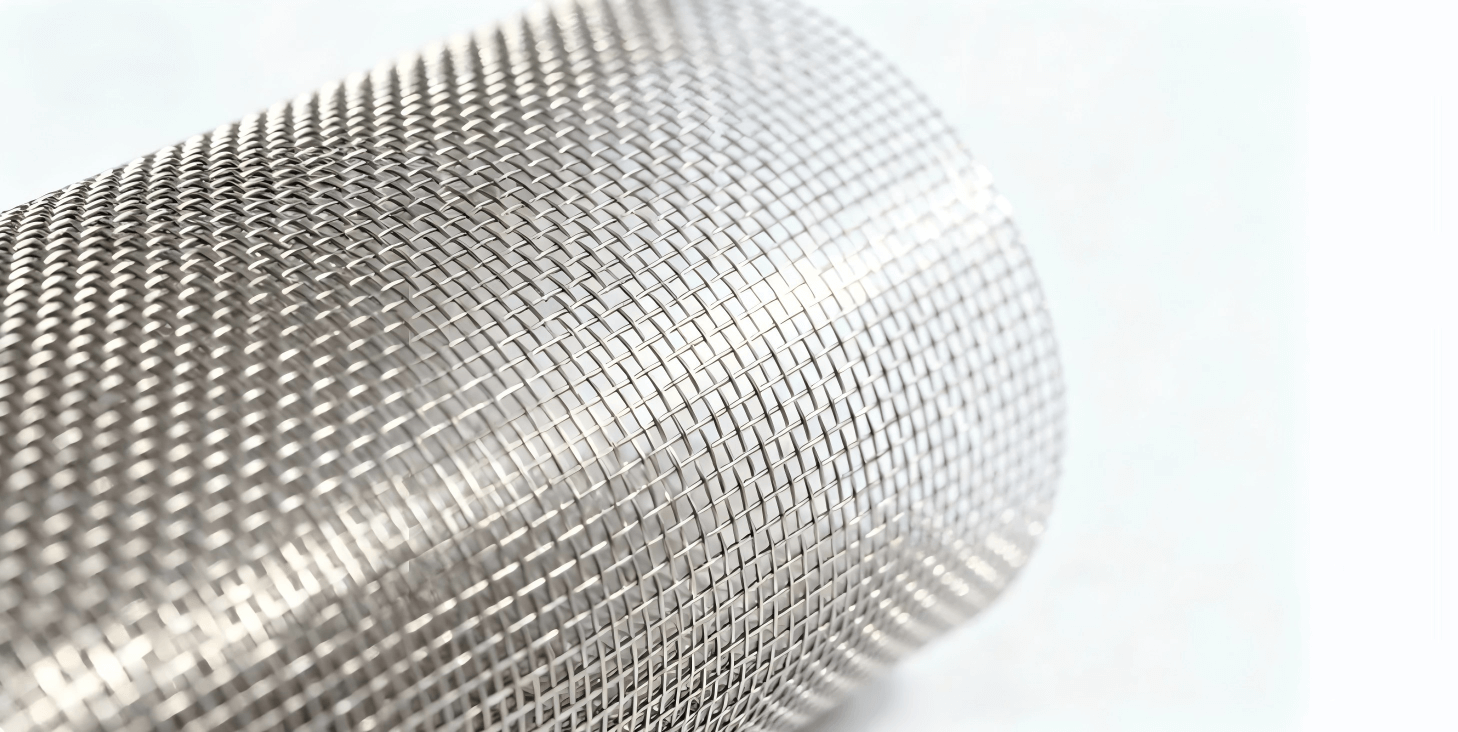

Stainless steel wire mesh is the most common filtration medium used inside

screen packs and continuous melt filters.

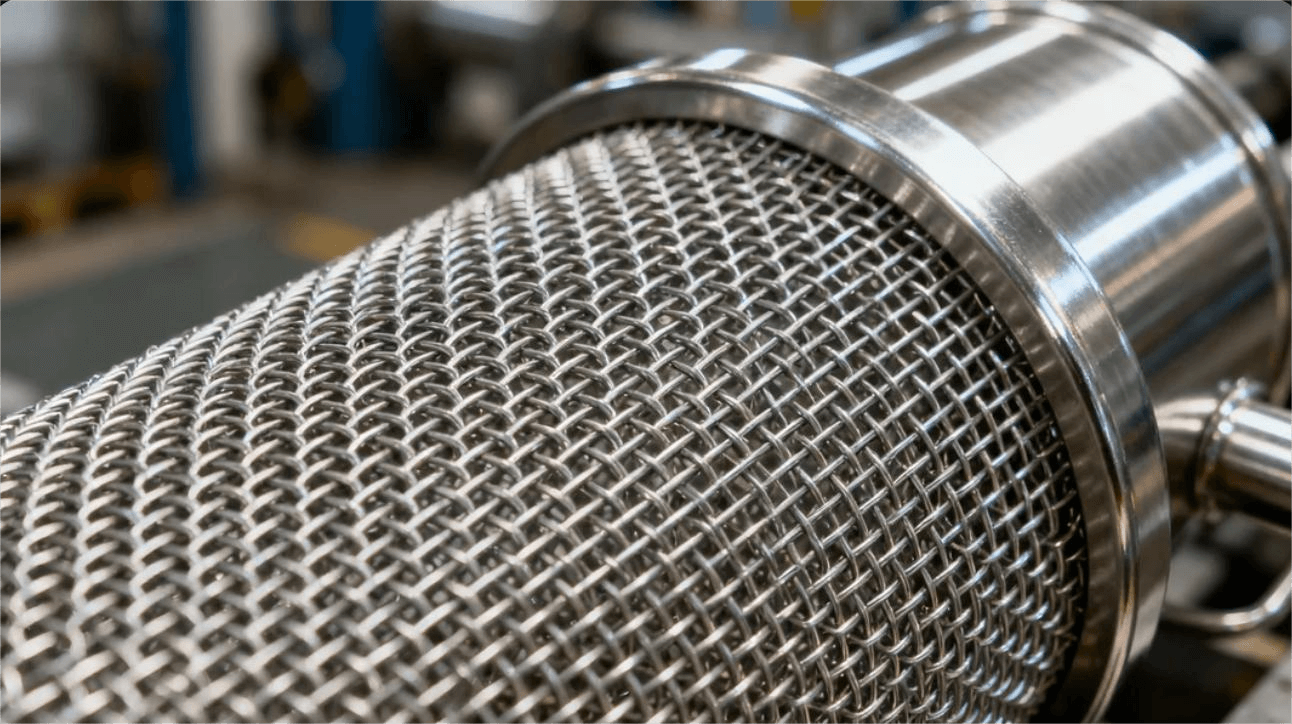

Why Stainless Steel Wire Mesh Is Used for Plastic Melt Filtration

High Temperature Resistance

Plastic extrusion typically operates between 180°C and 300°C.

Stainless steel wire mesh maintains mechanical strength and aperture stability

under continuous high-temperature conditions.

Precise Filtration Accuracy

Wire mesh can be woven with precise micron openings,

commonly ranging from 20 to 200 microns,

allowing manufacturers to control melt cleanliness without excessive pressure drop.

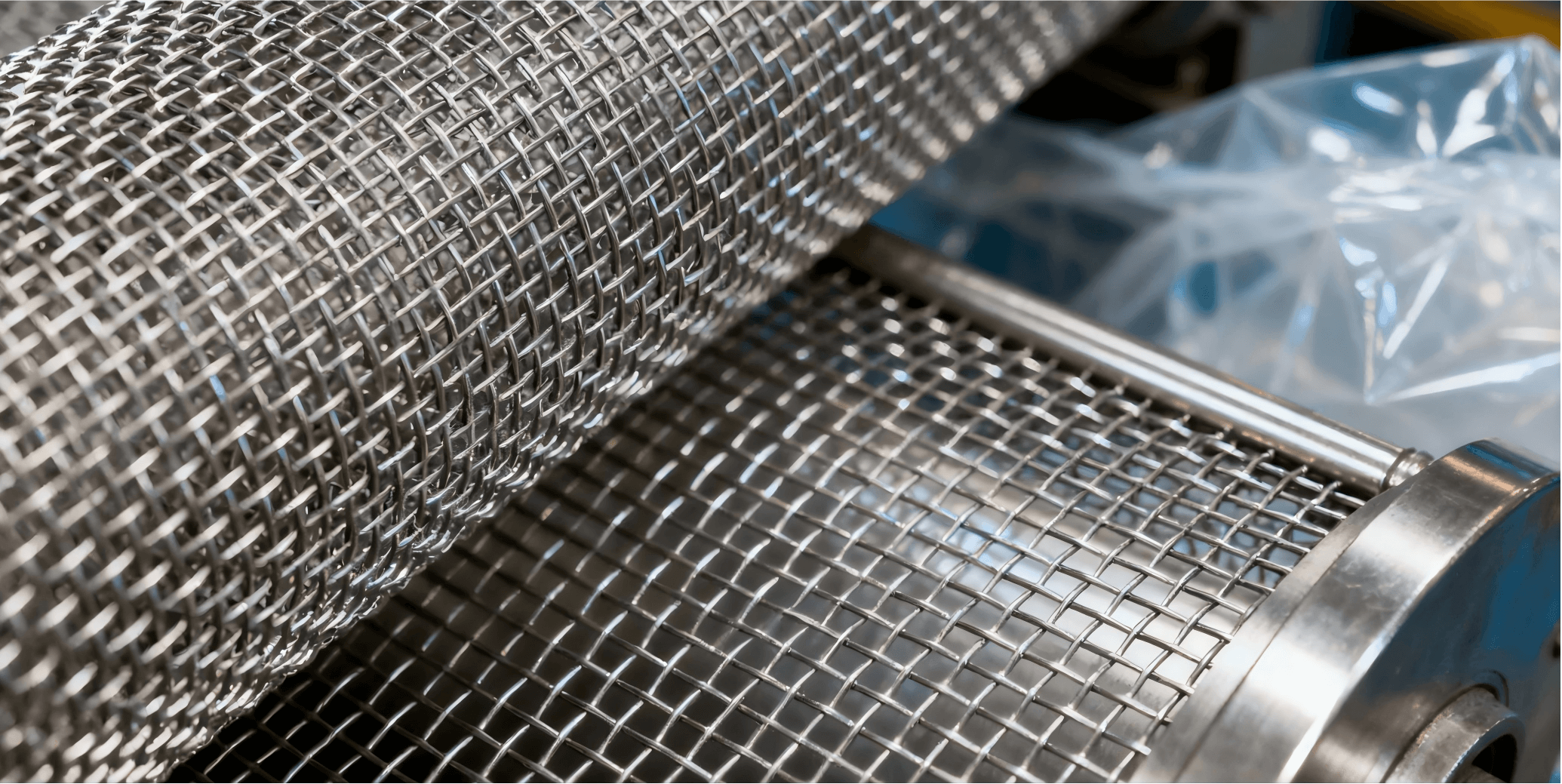

Compatibility with Screen Packs

Stainless steel mesh is easily layered into

extrusion screen packs,

making it suitable for both manual and automatic screen changers.

Real Case Study: Blown Film Extrusion for Flexible Packaging

Industry Background

A flexible packaging manufacturer in Southeast Asia produces multilayer PE films

for food and consumer goods packaging.

The production line includes a blown film extrusion system

processing recycled and virgin polymer blends.

The Filtration Challenge

The use of recycled resin introduced contaminants such as carbonized particles and gels.

These impurities caused frequent die buildup, unstable bubble formation,

and surface defects in finished films.

The Solution

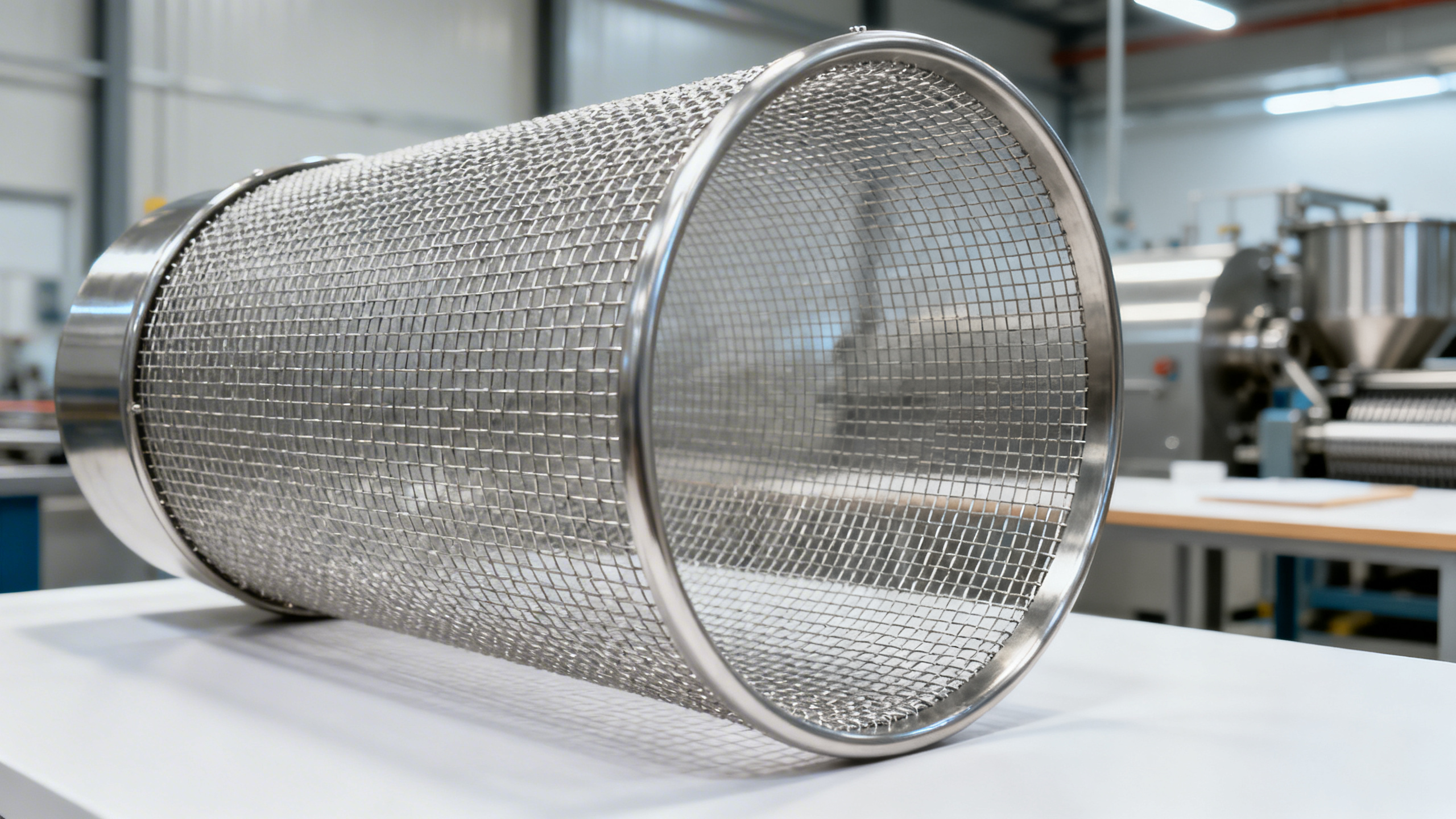

The manufacturer implemented a stainless steel wire mesh screen pack

consisting of multiple layers:

- Outer support layers: 20-mesh stainless steel wire mesh

- Filtration layers: 80-mesh and 120-mesh stainless steel mesh

The mesh pack was installed upstream of the extrusion die

and replaced on a scheduled maintenance cycle.

The Results

- Film defect rate reduced by over 50%

- Die cleaning frequency reduced from daily to weekly

- More stable extrusion pressure and melt flow

- Improved consistency in film transparency and thickness

Other Flexible Packaging Applications of Stainless Steel Mesh

Cast Film Extrusion

Used in CPP and PET cast film lines to remove fine contaminants

that affect surface smoothness and printability.

Recycled Plastic Processing

Stainless steel mesh plays a key role in filtering recycled polymer melts,

supporting sustainable packaging initiatives.

Masterbatch and Compound Filtration

Mesh filters ensure uniform dispersion of additives and pigments

during masterbatch production.

Frequently Asked Questions (FAQ)

What mesh size is commonly used for plastic extrusion melt filtration?

Most flexible packaging applications use stainless steel wire mesh

between 40 and 120 mesh, depending on polymer type and contamination level.

Is stainless steel mesh reusable in extrusion filtration?

In most cases, extrusion mesh is replaced rather than cleaned,

but stainless steel provides consistent performance and high temperature resistance.

Conclusion

This real-world example demonstrates that

stainless steel wire mesh for plastic extrusion melt filtration

is essential for quality control in flexible packaging production.

By improving melt cleanliness and process stability,

stainless steel mesh helps manufacturers reduce waste,

increase uptime, and meet demanding packaging standards.

Contact our technical team to select the right wire mesh

for your plastic extrusion application.