Stainless Steel Wire Mesh Screen Pack for Recycled Plastic Film Filtration

In the flexible packaging industry, the use of recycled polymers is increasing rapidly.

However, recycled materials often contain contaminants that negatively affect film quality.

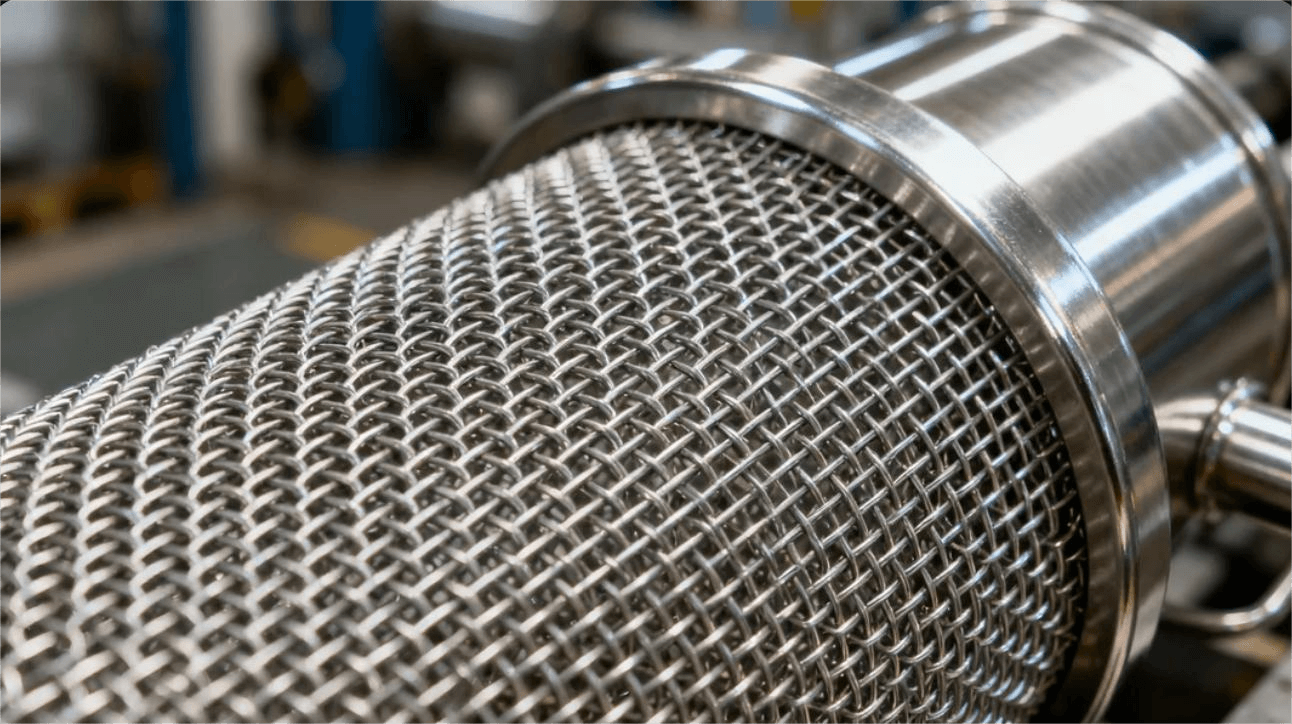

A stainless steel wire mesh screen pack for recycled plastic film filtration

is a proven solution widely used in industrial extrusion lines to improve melt cleanliness

and production stability.

What Is a Screen Pack in Plastic Film Filtration?

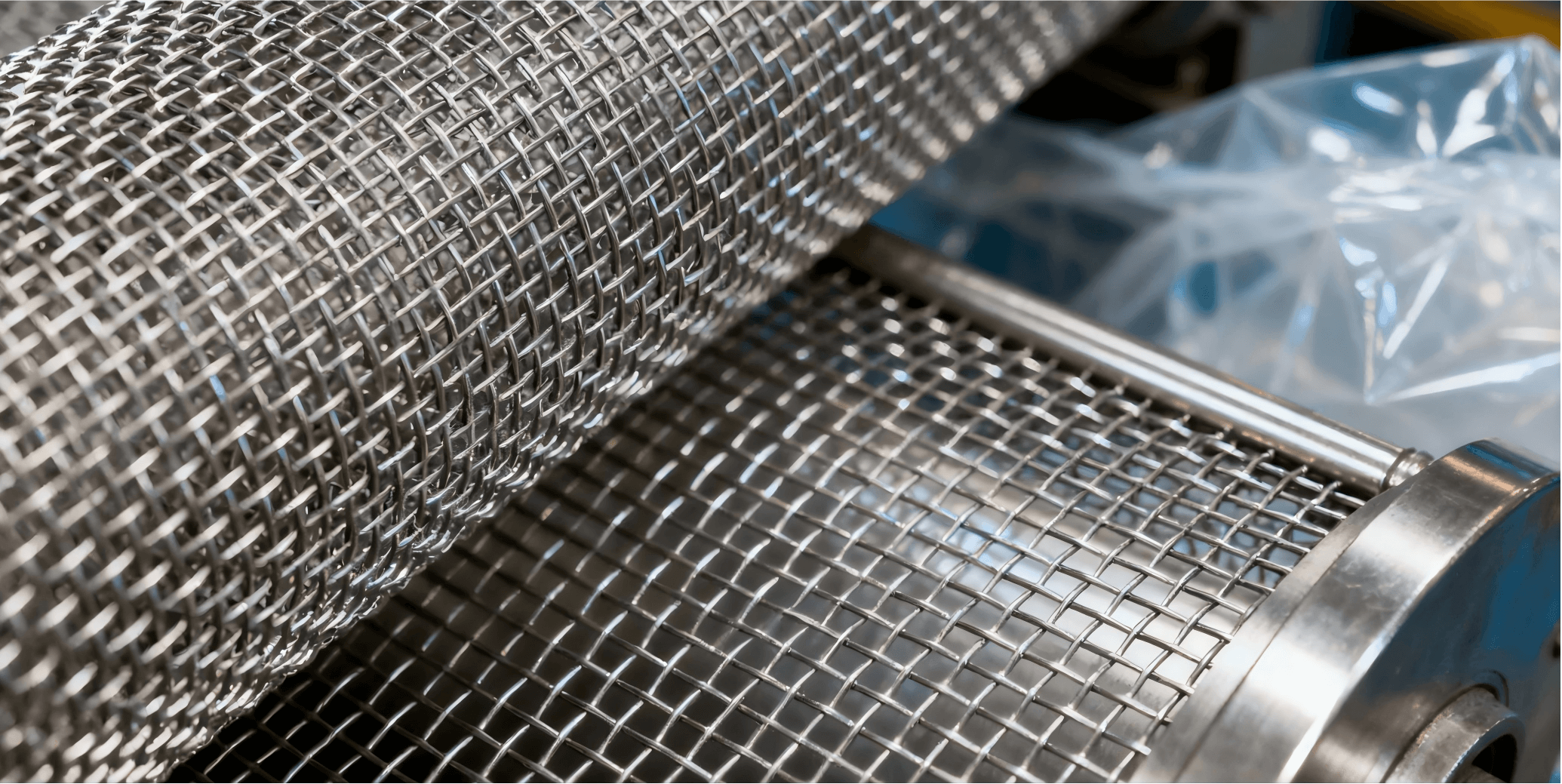

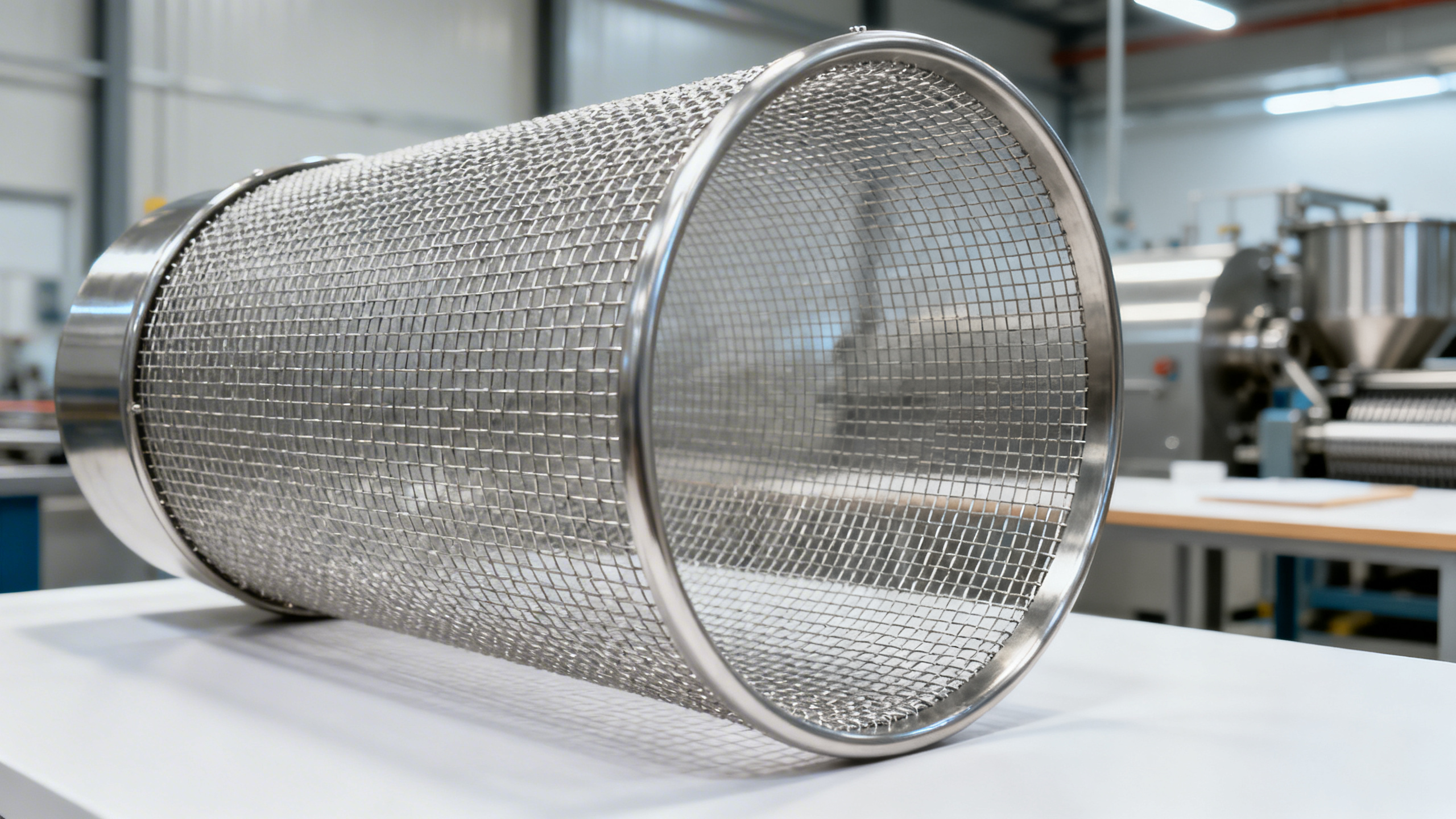

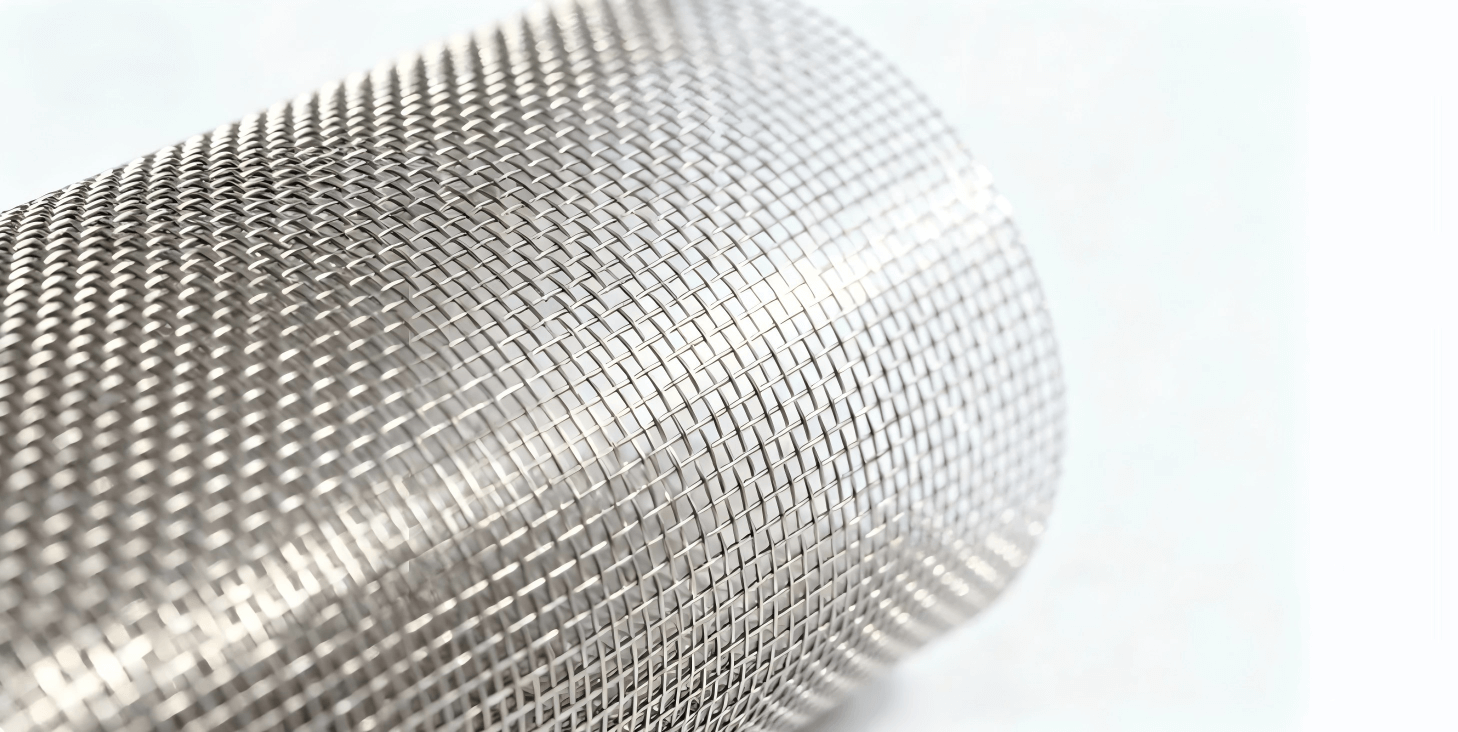

A screen pack is a layered filtration assembly installed in plastic extrusion systems.

It typically consists of multiple layers of stainless steel wire mesh

placed before the extrusion die.

In recycled plastic film production, screen packs serve a critical function:

they remove solid contaminants, gels, carbonized particles, and unmelted polymer fragments

from the molten plastic stream.

Why Stainless Steel Wire Mesh Is Used in Recycled Film Filtration

Thermal Stability in High-Temperature Extrusion

Plastic film extrusion for flexible packaging commonly operates between 190°C and 280°C.

Stainless steel wire mesh maintains its mechanical strength and pore accuracy

under continuous thermal stress.

Consistent Filtration Performance

Compared with fiber or polymer filters, stainless steel mesh provides

uniform and predictable filtration.

This is essential when processing recycled materials with variable contamination levels.

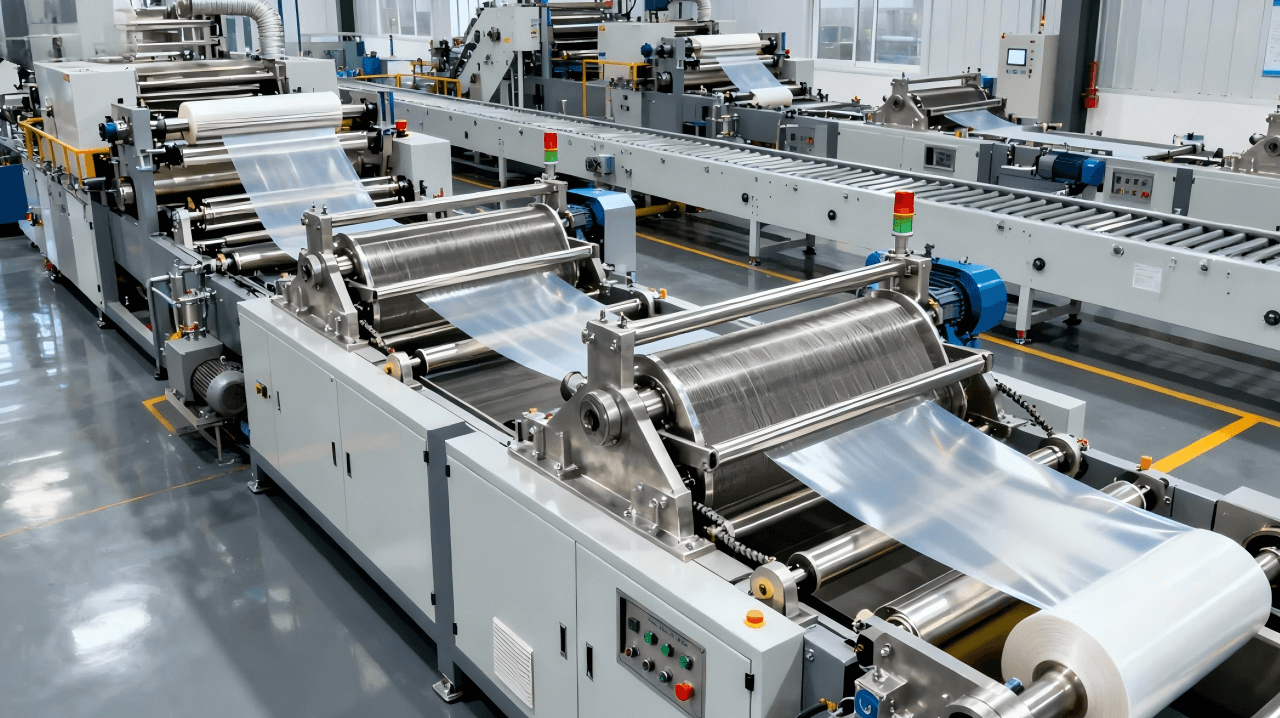

Compatibility with Automatic Screen Changers

Stainless steel mesh screen packs are fully compatible with

continuous screen changers,

allowing filtration without stopping production.

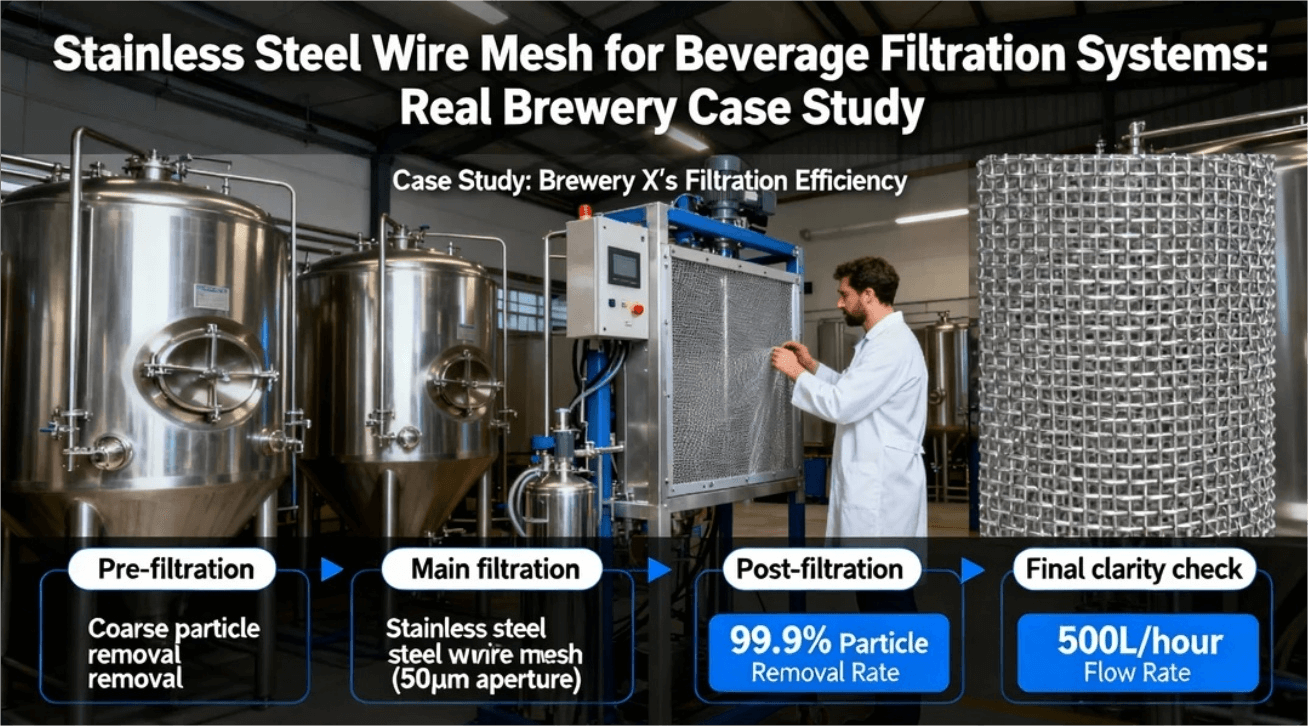

Real Industry Case: Recycled PE Film for Flexible Packaging

Production Background

A flexible packaging manufacturer in Eastern Europe produces recycled PE films

used for secondary food packaging and industrial wrapping.

The extrusion line processes post-consumer recycled (PCR) polyethylene.

Filtration Challenge

The recycled resin contained paper fibers, aluminum residues, and degraded polymer gels.

These impurities caused frequent die buildup, unstable extrusion pressure,

and visible defects in finished films.

Implemented Filtration Solution

The manufacturer installed a stainless steel wire mesh screen pack

with the following configuration:

- Support layer: 20 mesh stainless steel wire mesh

- Primary filtration layer: 60 mesh stainless steel wire mesh

- Fine filtration layer: 100 mesh stainless steel wire mesh

The screen pack was integrated into an automatic screen changer

located upstream of the flat die.

Measured Results

- Die cleaning frequency reduced by more than 60%

- Film surface defects reduced significantly

- More stable melt pressure during long production runs

- Higher acceptance rate for recycled-content packaging films

Other Flexible Packaging Applications of Screen Pack Filtration

Blown Film with Recycled Content

Screen packs are essential in blown film extrusion lines

to prevent bubble instability caused by melt contamination.

Cast Film and Lamination Films

High-clarity films used in lamination require clean melts,

making stainless steel mesh filtration a standard process step.

Masterbatch and Compound Preparation

Wire mesh screen packs help ensure uniform dispersion of additives

before film extrusion.

Frequently Asked Questions

What mesh sizes are commonly used for recycled plastic film filtration?

Most recycled film applications use stainless steel wire mesh

between 40 and 120 mesh, depending on contamination level and film thickness.

Are stainless steel screen packs disposable?

In most extrusion operations, screen packs are replaced after use.

Stainless steel ensures consistent filtration performance throughout the service life.

Conclusion

This real flexible packaging case demonstrates that a

stainless steel wire mesh screen pack for recycled plastic film filtration

is essential for achieving stable extrusion, improved film quality,

and efficient use of recycled polymers.

As sustainability requirements continue to grow,

screen pack filtration remains a core technology in modern plastic film production.

Contact our technical team to select the right wire mesh solution

for your recycled plastic film line.