Sintered Metal Filters for High-Temperature Applications: The Ultimate Filtration Solution

In industries where high-temperature processes are standard, filtration systems need to offer more than just particle removal—they must withstand extreme heat, maintain structural integrity, and ensure continuous operation. Sintered metal filters for high-temperature applications are specifically designed to meet these demands, delivering superior durability, precision, and longevity in harsh industrial environments.

What Are Sintered Metal Filters?

The Sintering Process Explained

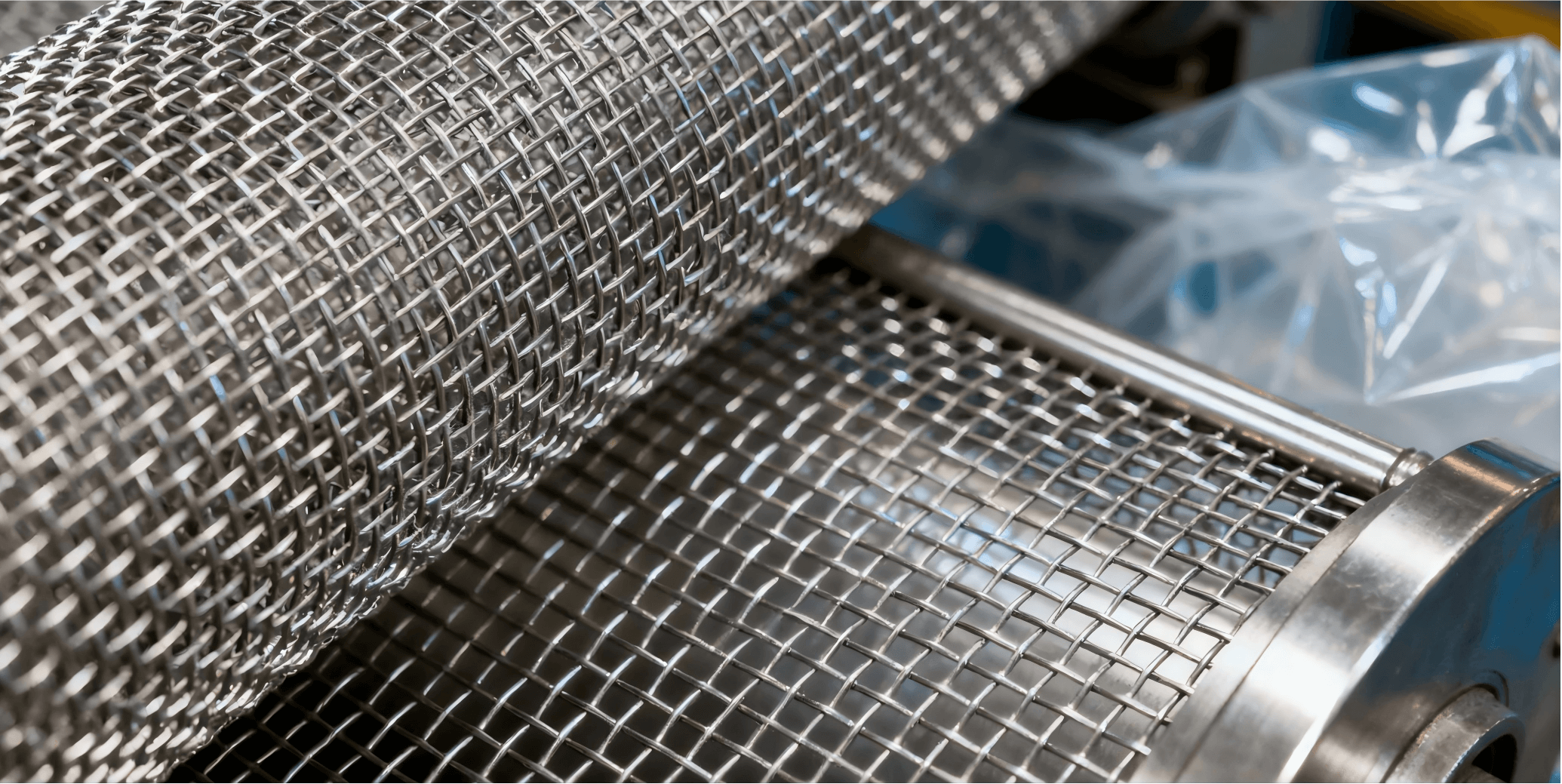

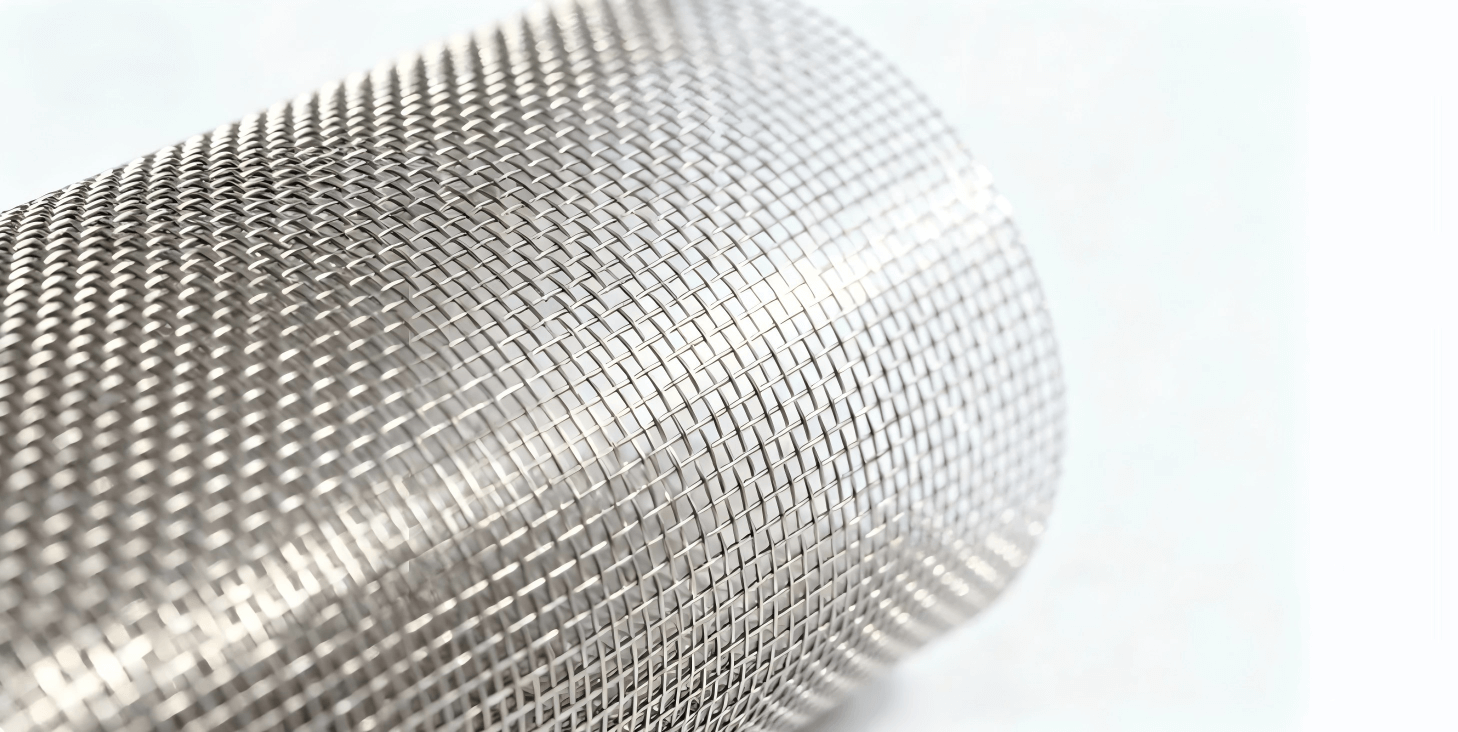

Sintered metal filters are produced by compressing and sintering fine metal powders or fibers at high temperatures. This process fuses the particles together without melting them, creating a porous yet robust structure capable of fine filtration.

Materials Commonly Used in Sintered Filters

Typical materials include stainless steel (304, 316L), Inconel, Monel, and Hastelloy, chosen based on chemical compatibility and temperature requirements.

Key Benefits of Sintered Metal Filters in High-Temperature Environments

Exceptional Thermal Stability and Strength

Sintered metal filters can operate in temperatures exceeding 600°C (1100°F) without deforming or losing filtration efficiency, making them ideal for critical processes.

High Precision Filtration Performance

With controlled pore sizes ranging from 0.5 to 200 microns, these filters provide consistent particle retention even under high-pressure and high-temperature conditions.

Extended Service Life and Reusability

Unlike disposable filters, sintered metal elements can be cleaned and reused multiple times through backflushing, ultrasonic cleaning, or chemical treatments, reducing operational costs.

Industrial Applications of Sintered Metal Filters

Petrochemical and Refining Plants

Used in catalyst recovery, gas filtration, and fluidized bed processes, sintered filters handle aggressive chemicals and high temperatures without performance degradation.

Power Generation and Gas Turbine Systems

In gas turbines and power plants, sintered metal filters protect sensitive equipment from particulate contamination in hot air and gas streams.

Pharmaceutical and Food Processing Industries

For applications requiring both thermal resistance and hygienic standards, sintered filters provide sterile filtration with easy cleaning procedures.

How to Select the Right Sintered Metal Filter for Your Process

Pore Size Selection Based on Filtration Needs

Determine the particle size to be filtered and select a sintered filter with a precise and uniform pore size to ensure optimal performance.

Choosing the Right Metal Alloy for High-Temperature Exposure

For standard applications, 316L stainless steel is sufficient, but for extreme temperatures or corrosive media, alloys like Inconel or Hastelloy offer superior resistance.

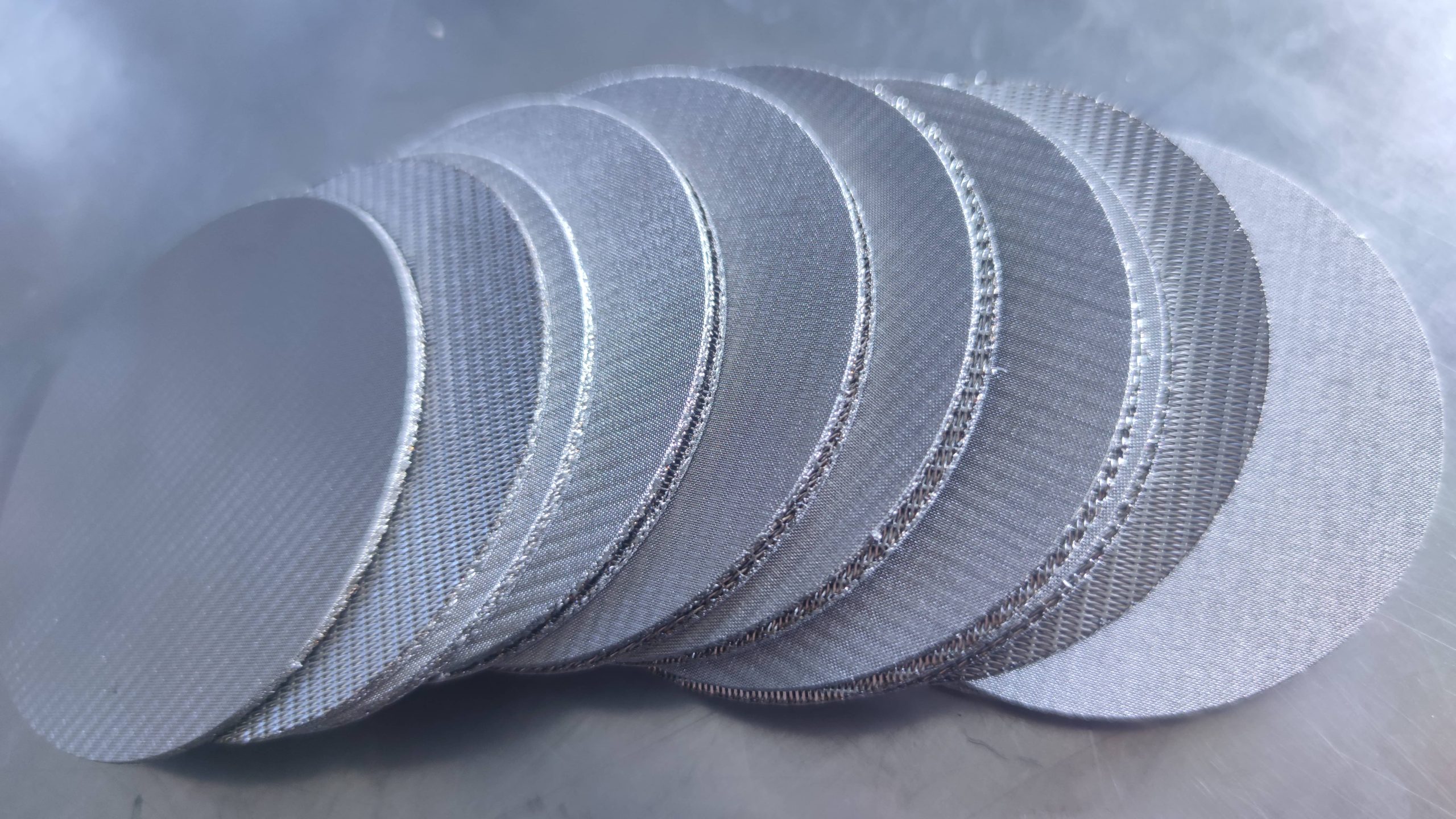

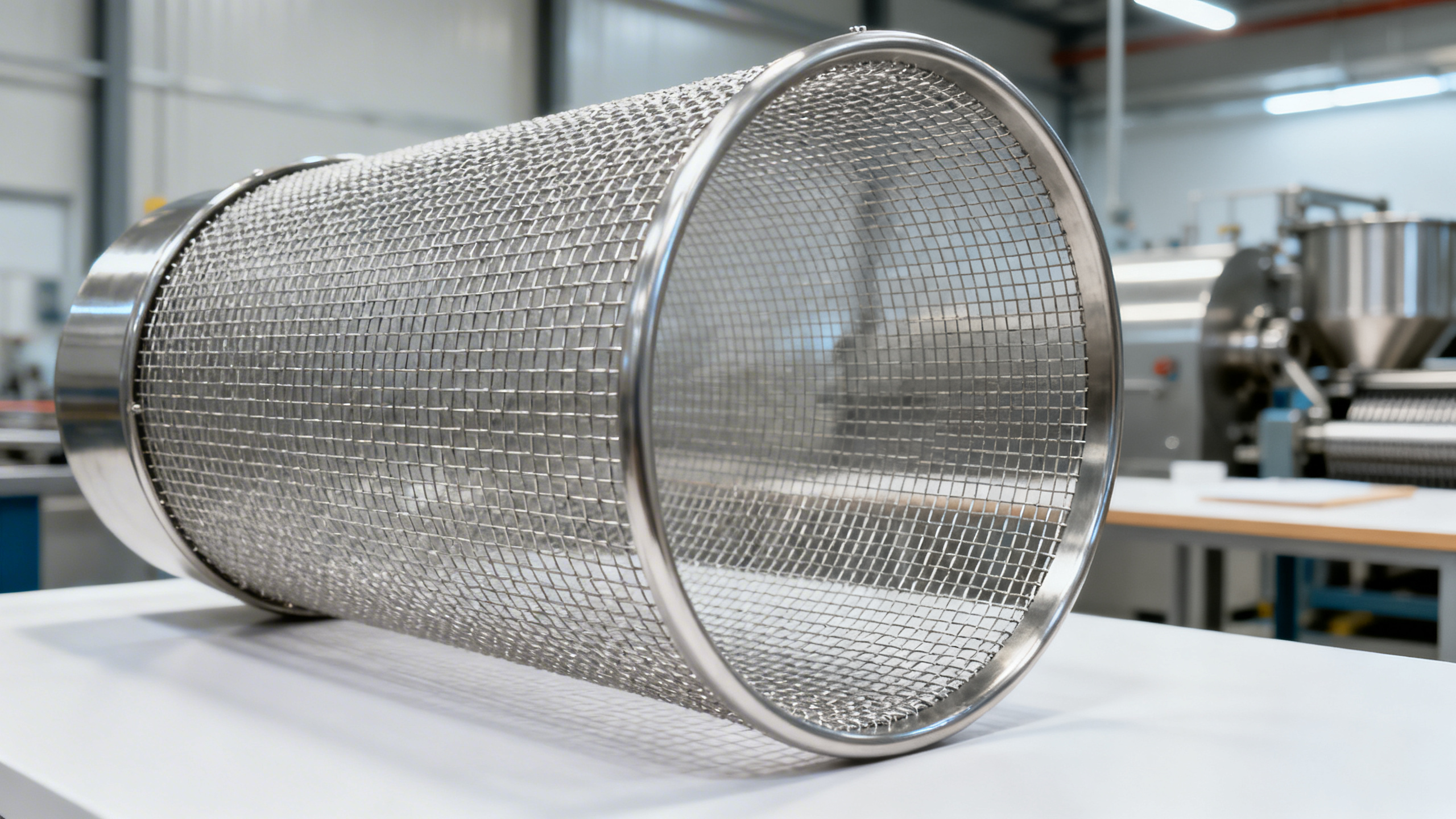

Customization Options: Shapes, Layers, and Surface Treatments

Sintered metal filters can be tailored to fit specific systems—available in cartridges, discs, cones, and pleated formats. Surface treatments like electropolishing can enhance cleanability and durability.

✅ Conclusion

Sintered metal filters for high-temperature applications are the preferred choice across industries that demand high-performance filtration in extreme conditions. Their durability, reusability, and precision make them a cost-effective and reliable solution for critical processes. Interested in customized sintered filter solutions? Contact our technical experts today to discuss your application requirements.